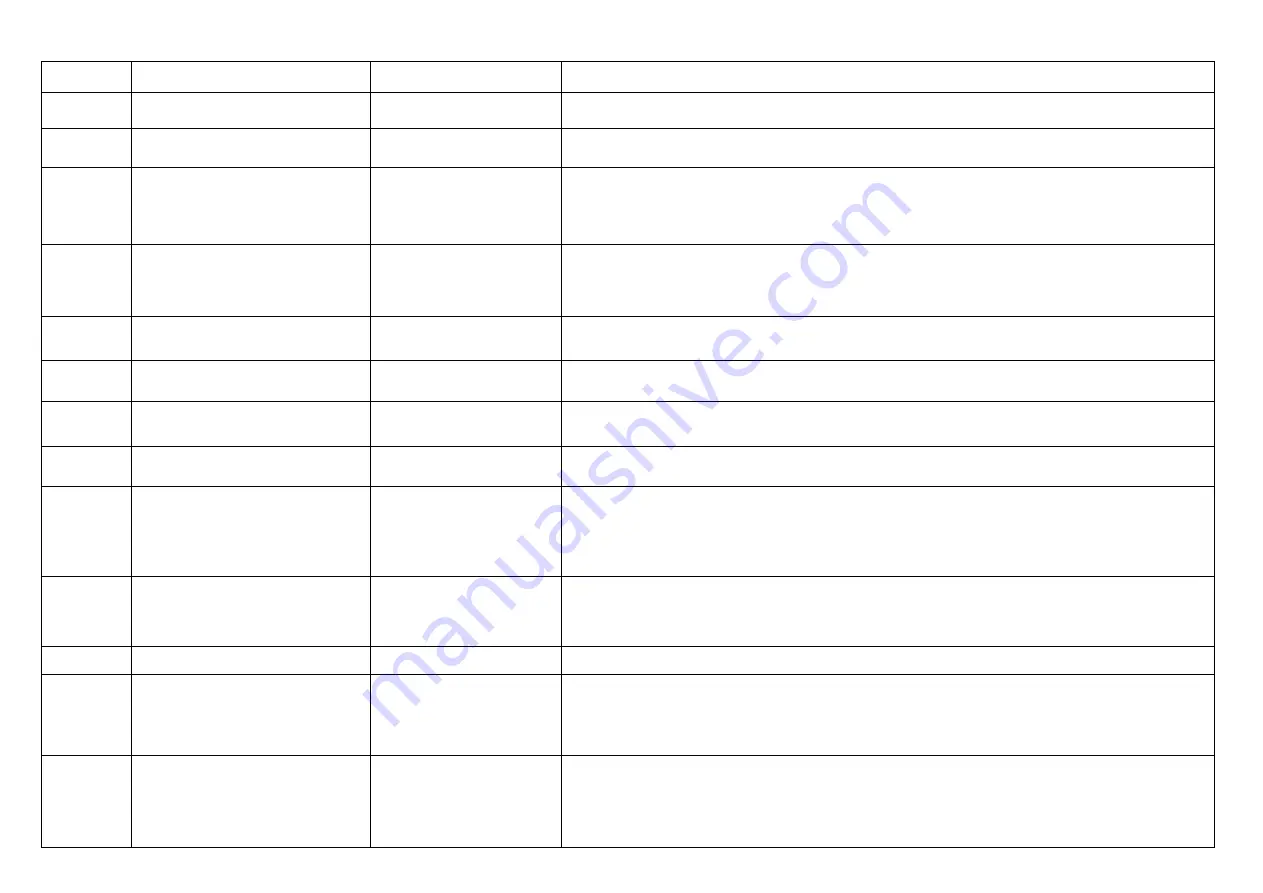

57

14.2. Error Code Instruction

Error code Error name

Relevant parts information

Review and resolve

E04

Electric heater over heat Protection

1. Check the Electrical heating Overheat protector open or not.

2. Check the Electrical heater.

E08

Communication failure between PCB

and display

Communication error

between PCB and DISPLAY

1. Check cable connection of PCB and DISPLAY.

2. Check the software version of PCB and DISPLAY.

E11

HP Protection

HP switch is open

1. Check whether showing the error after unit shutdown.

2. Measure the discharge pressure when unit is running.

3. Detect EEV step, suction pressure, inlet/outlet water discharge and suction temp.

4. Release all the gas of the system and refill refrigerant according to the nameplate.

E12

LP Protection

LP switch is open

1. Check whether showing the error after unit shutdown.

2. Measure the suction pressure when unit is running.

3. Detect EEV step, discharge pressure, inlet/outlet water discharge and suction temp.

4. Release all the gas of the system and refill refrigerant according to the nameplate.

E19

Primary Anti-freezing Protection

Ambient temp.≤0

℃

, A04-2

℃

≤ water inlet≤A04

℃

It is the protection in winter. Once the water temperature rises up to A04+4

o

C or the ambient temp is higher

than 1, the error code disappears.

E29

Secondary Anti-freezing Protection

Ambient temp.≤0

℃

, water

inlet≤A04-2

℃

It is the protection in winter. Once the water temperature up to A04+11

o

C or the ambient temp is higher

than 1, the error code disappears.

E19

Primary Anti-freezing Protection

Ambient temp.≤0

℃

, 2

℃

≤

water inlet≤4

℃

It is the protection in winter. Once the water temperature rises up to 8

o

C or the ambient temp is higher than

1

o

C, the error code disappears.

E29

Secondary Anti-freezing Protection

Ambient temp.≤0

℃

, water

inlet≤2

℃

It is the protection in winter. Once the water temperature up to 15

o

C or the ambient temp is higher than 1

o

C, the error code disappears.

E032

Flow Switch Protection

Flow switch is open

1. Detect the connection of cables.

2. Detect the flow switch.

3. Detect the water valve is opened or opened fully.

4. Detect the water pump and the filter.

5. Maybe there is some air in the water route.

E051

Compressor Over current Shutdown

Fault

Compressor Over current

1. Check ambient temp. and inlet/outlet water temp.;

2. Turn on the unit. Record and analyze the changing process of high/low pressure, discharge/suction

temp., EEV step, compressor frequency and running current.

3. If they are OK, replace a new compressor driver board.

E065

High water outlet temp. protection

Check if the water flow is too low and the outlet water whether too high

E081

Communication failure between PCB

and fan drive board

Communication error

between PCB and fan drive

board

1. Check the connection between PCB and fan board. All of 12V-12V, GND-GND, A-A, B-B should be

closed;

2. If they are closed, turn on the power, then measure the voltage between 12V and GND on fan board, if

higher than 15V or lower than 7V, replace a new fan board.

E103

Fan motor overload protection

1. Check if the fan motor running well.

2. Detect the current of fan motor.

3. If the current is more than 1A, it means the motor have problem and need to replace a new one.

4. If the current is less than 1A, it means the motor control module have problem and nee to replace a new

one.