2-1

3

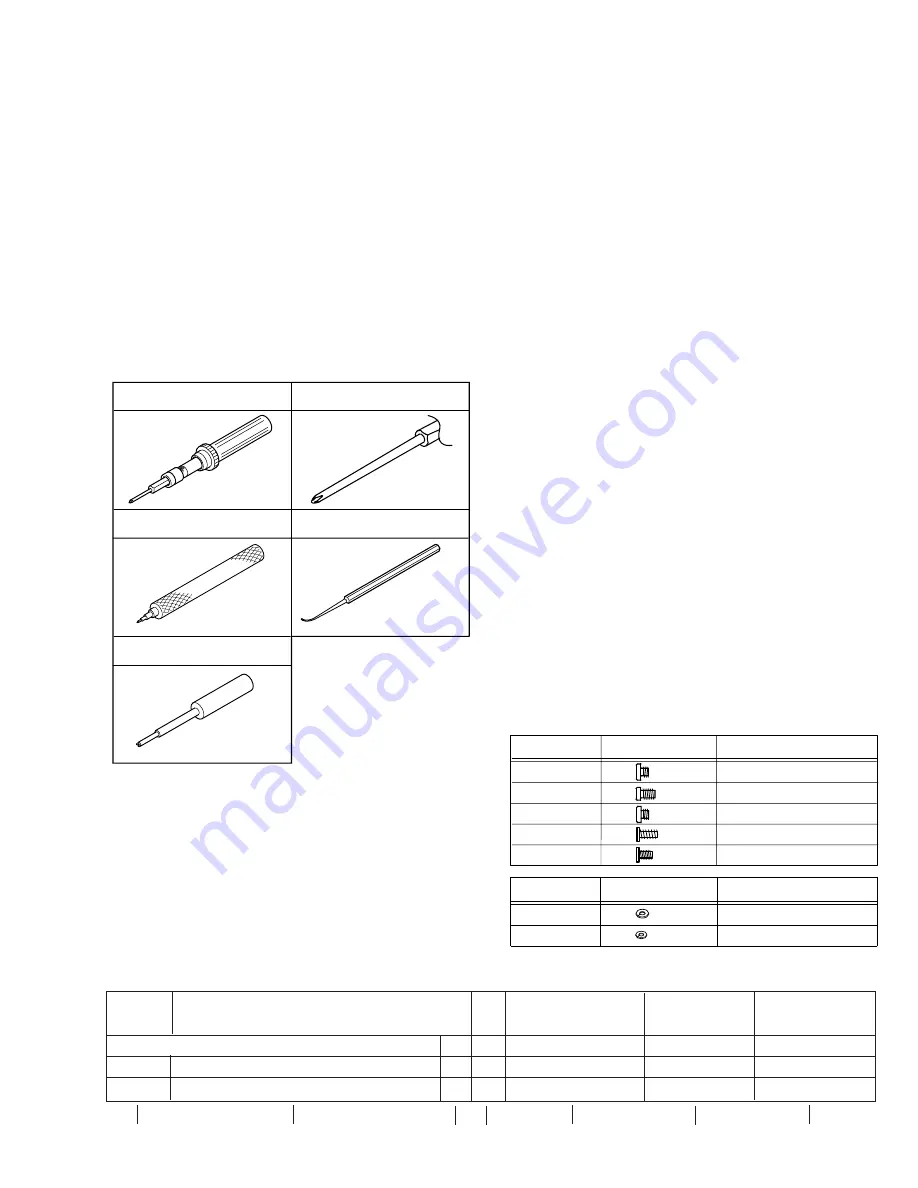

Bit

YTU94088-003

1

2

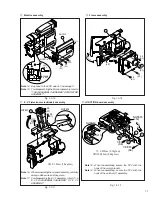

Torque driver

YTU94088

Slit washer fitting jig

YTU94121A

5

4

Chip IC replacement jig

PTS40844-2

Guide driver

YTU94148A

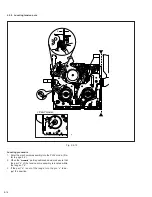

A

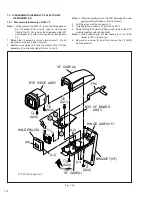

Cassette housing assembly

T

M1

3(S1),(L1)-(L4)

1,28,29,30

Adjustment

1

Reel disk (SUP) assembly

T

M2

(W1)

2,3

2

Reel disk (TU) assembly

T

M2

(W1)

2,3

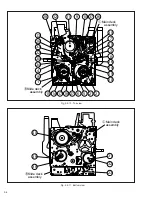

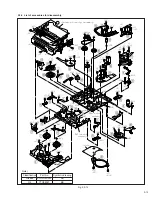

SECTION 2

MECHANISM ADJUSTMENT

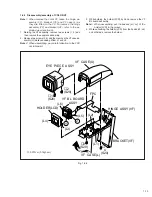

Fig. 2-1-1

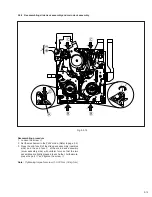

2.1 PRELIMINARY REMARKS ON ADJUSTMENT AND RE-

PAIR

2.1.1 Precautions

1. When fastening parts, pay careful attention to the tightening

torque of each screw. Unless otherwise specified, tighten a

screw with the torque of 0.04 N·m (0.4 kgf·cm).

2. Be sure to disconnect the set from the power supply before fas-

tening and soldering parts.

3. When disconnecting/connecting wires, be careful not to get them

and their connectors damaged. (Refer to the Section 1.)

4. When replacing parts, be very careful neither to damage other

parts nor to fit wrong parts by mistake.

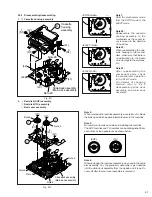

2.1.2 Necessary jigs

Table 2-1-1

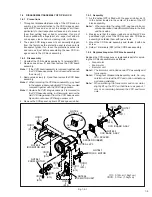

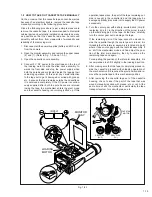

2.1.3 Notes on disassembling/reassembling procedure

The disassembling procedure table (Table 2-2-2 on page 2-5,

a part of the table is shown below for reference) shows the

procedure to disassemble/reassemble mechanism parts.

Carefully read the following explanation before starting actual

disassembling/reassembling work. The item numbers (circled

numbers) in the following explanation correspond to those

appearing under respective columns of the table.

(1)

Circled numbers appearing in this column indicate the

order to remove parts. When reassembling, follow these

numbers in the reverse order. Circled numbers in this

column correspond to those appearing in drawings of

this section.

(2)

This column shows part names corresponding to circled

numbers in the left column.

(3)

The symbol (T or B) appearing in this column shows the

side which the objective part is mounted on.

T = the upper side, B = the lower side

(4)

Symbols appearing in this column indicate drawing

numbers.

(5)

This column indicates parts and points such as screws,

washers, springs, and others to be removed/fitted for dis-

assembling/reassembling the mechanism. Besides such

the parts, this column occasionally indicates working

points.

P = Spring

W = Washer

S = Screw

Lock (L), soldering (SD), shield, connector (CN), etc.

Example

• Remove (W1) = Washer W1.

• Remove the solder at (SD1) = Point SD1.

• Disconnect

A

= Connector

A

.

(6)

Numbers in this column represent the numbers of notes

in the text. For example, “1” means “Note 1”.

( F o r p a r t s t h a t n e e d p h a s e a d j u s t m e n t a f t e r re-

assembling, refer to “2.2.7 Check and adjustment of

mechanism phase”.)

(7)

This column indicates required after-disassembling/-

reassembling work such as phase adjustment or

mechanism adjustment.

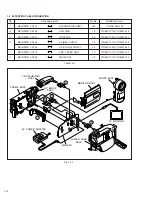

2.1.4 Screws and washers used in mechanism

Table 2-1-1 shows screws and washers used in the mechanism

by the part numbers with their respective symbols,

shapes and colors.

When disassembling/reassembling the mechanism, be careful

not to make any mistake in removing/refitting screws and

washers.

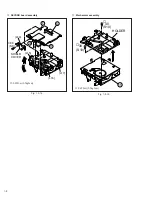

Step

Part Name

Fig.

W1

W2

YQ44246

YQ44246-2

Shape

Parts No.

Symbol

Shape

Parts No.

Symbol

(S1)

(S2)

(S3)

(S5)

YQ43893-4

YQ43893-2

YQ43893

QYSLSP2030D

(S4)

QYSLSF2055D

Point

Note

Remoarks

(1)

(2)

(3)

(4)

(5)

(6)

(7)

5

5

5

5

5

5

5