E 21

0606

.GB

6.5

Travel parameters

Z

For trucks without a display instrument (CANDIS (

o

)) the code lock parameters can

only be set by the manufacturer's service department.

The following example shows the parameter setting for the acceleration of travel

program 1 (parameter 101).

Acceleration example

– Enter the three digit parameter number (101) and confirm with the Set key (16).

– Check the LC display of the display instrument (CANDIS (

o

)) (parameter number

and current parameter value are displayed).

Z

If there is no input for approx. 5 seconds, the display switches back to showing the

operating hours.

F

If a parameter number other than the one desired is displayed, you must wait until the

operating hours are displayed again.

– Enter the parameter according to the parameter list or change and confirm with the

Set key (16).

– Check the LC display of the display instrument (CANDIS (

o

)), confirm with the Set

key (16).

– The LED (15) of the

o

key (20) switches briefly to a steady light and starts flashing

again after approx. 2 seconds.

Z

If the entry is incorrect, the LED (15) of the

o

key (20) turns red. If you enter the

parameter number again the setting can be entered or changed.

Repeat the process to enter more parameters as soon as the LED (15) of the

o

key

(20) flashes. To finish entering, press the

o

key (20).

Z

Travel is disabled while the parameters are being entered. If the setting is to be

checked in programming mode, follow this sequence:

– Select the edited travel program after entering the parameter, and confirm with the

Set key (16).

– The truck is now in travel mode and can be checked.

– To continue setting, confirm with the Set key (16) again.

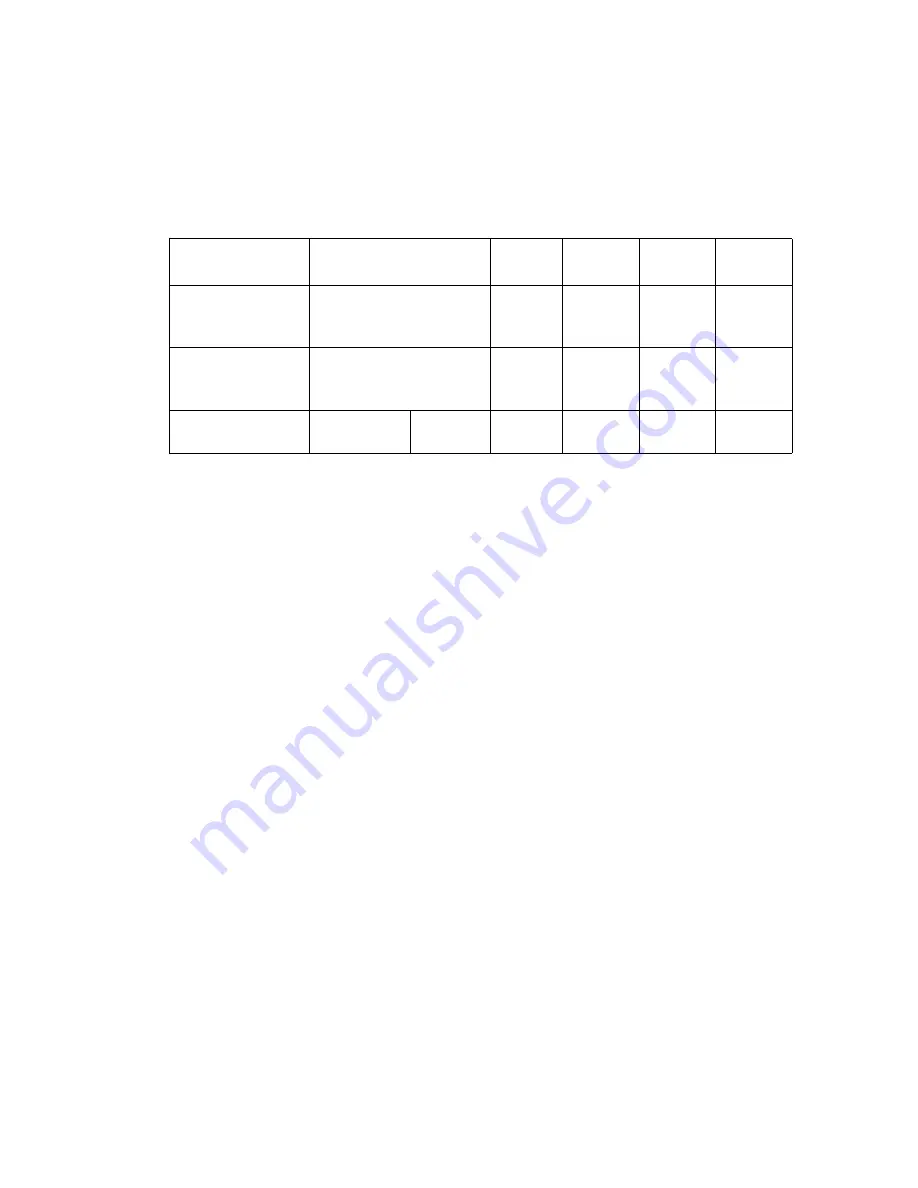

Display instrument

(CANDIS)

LED (20)

o

key

LED (17)

Key 1

LED (18)

Key 2

LED (19)

Key 3

Current

Setting

is displayed

101 6

Green

flashing

Off

Off

Off

Changed

Setting

is displayed

101 8

Green

flashing

Off

Off

Off

Parameter

number

Paramete

r setting

E 21

0606

.GB

6.5

Travel parameters

Z

For trucks without a display instrument (CANDIS (

o

)) the code lock parameters can

only be set by the manufacturer's service department.

The following example shows the parameter setting for the acceleration of travel

program 1 (parameter 101).

Acceleration example

– Enter the three digit parameter number (101) and confirm with the Set key (16).

– Check the LC display of the display instrument (CANDIS (

o

)) (parameter number

and current parameter value are displayed).

Z

If there is no input for approx. 5 seconds, the display switches back to showing the

operating hours.

F

If a parameter number other than the one desired is displayed, you must wait until the

operating hours are displayed again.

– Enter the parameter according to the parameter list or change and confirm with the

Set key (16).

– Check the LC display of the display instrument (CANDIS (

o

)), confirm with the Set

key (16).

– The LED (15) of the

o

key (20) switches briefly to a steady light and starts flashing

again after approx. 2 seconds.

Z

If the entry is incorrect, the LED (15) of the

o

key (20) turns red. If you enter the

parameter number again the setting can be entered or changed.

Repeat the process to enter more parameters as soon as the LED (15) of the

o

key

(20) flashes. To finish entering, press the

o

key (20).

Z

Travel is disabled while the parameters are being entered. If the setting is to be

checked in programming mode, follow this sequence:

– Select the edited travel program after entering the parameter, and confirm with the

Set key (16).

– The truck is now in travel mode and can be checked.

– To continue setting, confirm with the Set key (16) again.

Display instrument

(CANDIS)

LED (20)

o

key

LED (17)

Key 1

LED (18)

Key 2

LED (19)

Key 3

Current

Setting

is displayed

101 6

Green

flashing

Off

Off

Off

Changed

Setting

is displayed

101 8

Green

flashing

Off

Off

Off

Parameter

number

Paramete

r setting

Summary of Contents for EJC 212-220

Page 1: ...Operating Instructions 50460011 EJC 212 220 G 12 05 03 07 ...

Page 3: ...0108 GB ...

Page 7: ...0506 GB 2 ...

Page 9: ...1004 GB A 2 ...

Page 19: ...0306 GB B 10 ...

Page 35: ...0606 GB D 12 ...

Page 38: ...E 3 0606 GB 1 2 3 4 5 6 7 8 9 8 10 11 12 13 ...

Page 40: ...E 5 0606 GB 1 2 3 4 5 6 7 8 9 8 10 11 12 13 ...

Page 42: ...E 7 0606 GB 1 3 4 5 6 12 ...

Page 75: ...0307 GB F 14 ...

Page 93: ...0506 GB 18 ...