7

1.3 Scope of application

_________________________________________________________________________

Generalitie

Explosion protected pressure switches of the HNSPX-Ex type series with

intrinsic safety « i » and b enclosures « t » control and monitor pressure process.

The pressure switches operate according to a deformable sensor (membrane or

valve). The variation of pressure leads to a deviation of the membrane (or valve)

which acts on a electrical contact.

In gas area the pressure switches HNSPX-Ex could be only fitted to equipment

certificated with intrinsic safety and could be used in explosive areas – Zone 0,

Zone 1 and Zone 2.

In dust area the ignition protection class “t” allows the use of device in Zone 20,

Zone 21, Zone 22

If this pressure transmitter is used in an explosive area, you must observe the

instructions on installation and operation of equipment in this type of area.

_______________________________________________________________________

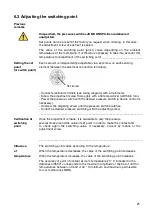

Do not damage the sensitive elements (diaphragm or piston) of the pressure

switch!

−

Do not use the device on a process fluid which could damage the pressure

switch. We would recommend you mount the device on a diaphragm seal if

available (Attention the filling liquid must be compatible with the process).

−

Execution with flush membrane (separator): Do not deform the membrane.

To touch the membrane with your fingers may be enough to cause damage.

−

Do not insert different objects into the outlet pressure !

−

The pressure of membrane must be uniform.

−

The pressure to be measured must not exceed the permissible overpressure,

even when pressure spikes.

−

Spiking very high pressure can destroy the switch. Under these conditions,

we must take adequate precautionary measures (eg. Ride a damping

element).

−

Do not exceed the maximum permissible fluid temperature (+85 ° C) and, if

applicable, use a cooler.

Avoid mounting close to sources of heat or

excessive sunlight to minimize the effects of condensation nocturnal.

Avoid falls and the locations where the material can undergo mechanical shock.

Summary of Contents for 405071

Page 4: ...4 ...

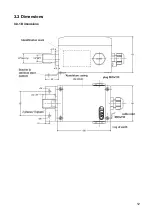

Page 12: ...12 3 3 Dimensions 3 3 1 Dimensions ...

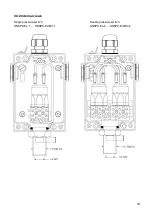

Page 14: ...14 3 3 3 Process connection ...

Page 23: ...23 8 Appendix ...

Page 24: ...24 ...

Page 25: ...25 ...

Page 26: ...26 ...

Page 27: ...27 ...

Page 28: ...28 ...

Page 29: ...29 ...

Page 30: ...30 ...

Page 31: ...31 ...

Page 32: ...32 ...