– 122 –

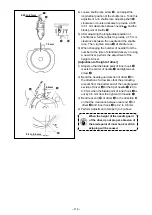

Do not wipe off the grease applied

onto the periphery of needle bar

inside the frame. If the grease has

decreased due to cleaning, air blow

or other reasons, apply grease

again without exceptions.

■

Adding grease to the needle bar upper and lower bushings section, slide block section and

intermediate presser bar lower bushing section

1) Open the frame cover to remove intermediate

presser auxiliary spring B

❶

.

2) Apply JUKI Grease A onto periphery of needle

bar

❷

. Turn the sewing machine by hand to

apply grease onto the entire periphery of the

needle bar.

3) Apply JUKI Grease A onto periphery of inter-

mediate presser bar

❼

.

Remove setscrew

❽

from the intermediate

presser bar bushing grease hole. Put JUKI

Grease A through inlet

❾

. Tighten screw

❽

to fill inside the bushing with JUKI Grease A.

4) Apply JUKI grease A to the surface of inter-

mediate presser spring

.

❷

❼

❽

❾

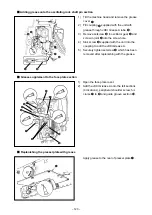

■

Adding grease onto the eccentric cam section

1) Open crank rod cover

❶

.

2) Remove setscrew

❸

from the

grease inlet cover located at periph-

ery of crank rod

❷

.

3) Fill coupling

❹

with grease through

JUKI Grease A tube

❺

.

4) Sink screw

❻

supplied with the unit

into the coupling to add the grease.

5) After adding the grease, securely

tighten setscrew

❸

which has been

removed.

The eccentric cam section

can be sufficiently filled with

grease by adding the grease

while turning the main shaft

of sewing machine.

❷

❶

❹

❷

❹

❺

❻

❸