– 31 –

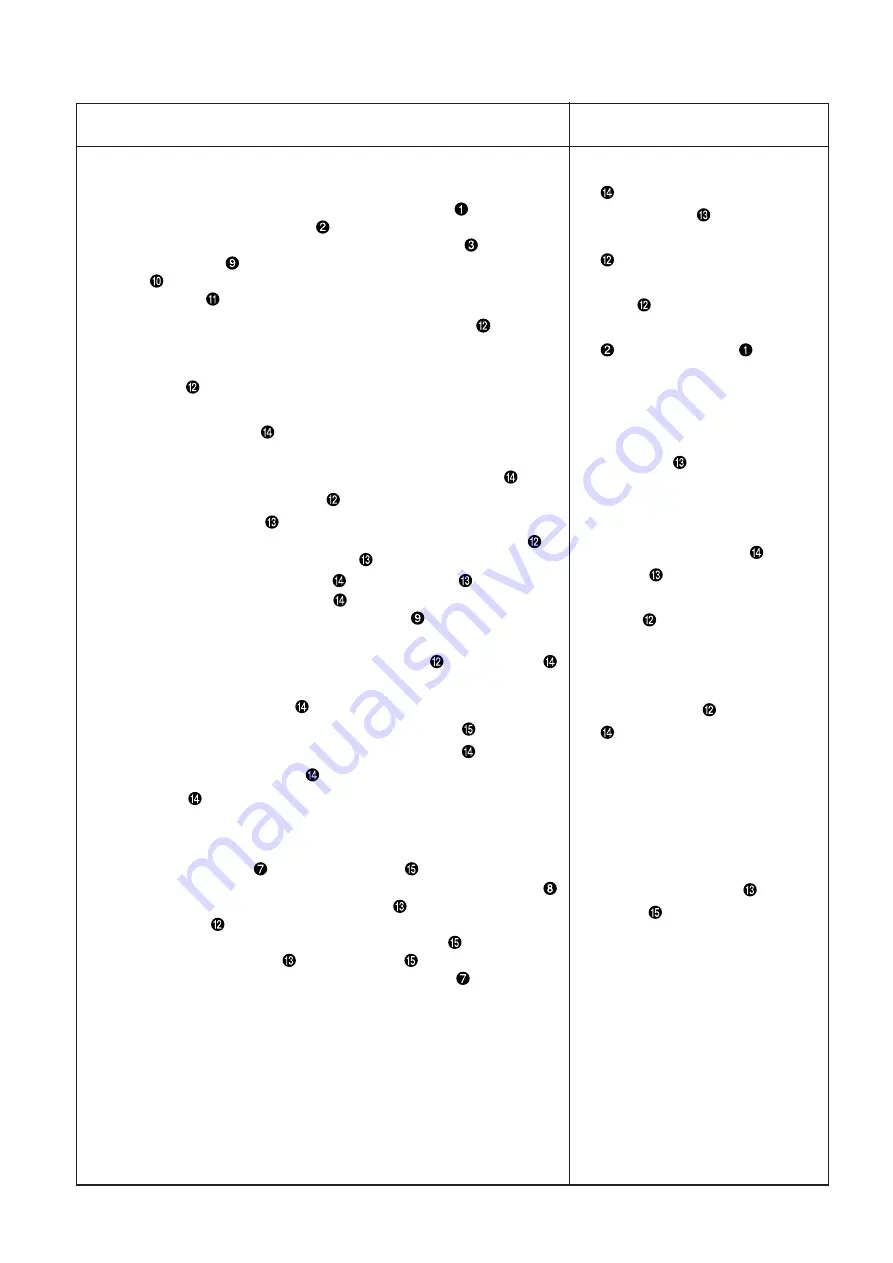

Adjustment Procedures

Results of Improper Adjustment

* Turn ON the power once, and turn OFF the power again after

making the intermediate presser in the lowered state.

1. Turn hand wheel by hand to ascend the needle bar

.

Adjust so that lower marker line

on the ascending needle bar aligns

with the bottom end of the needle bar bushing lower

.

2. Loosen setscrew

in the driver. Drawing bobbin case opening lover

hook

toward you, open it to the right and left until bobbin case

opening lover

comes off.

(Caution) At this time be careful not to let inner hook

come off

and fall.

3. Refer to 5. below and make tentative adjustments of timing for the

inner hook

.

4. Turn the pulley by hand and make adjustments for the needle loca-

tion block of the driver

by bending it in the direction of Arrow A so

that the clearance b attains 0mm to 0.5mm between the needle tip

and the lowest end of the needle location block of the driver

when

the needle tip of the inner hook

is protruded by 0.5mm from the

right end of the needle

.

5. Make an adjustment so that the blade point of the inner hook

is

aligned with the center of the needle

, and that the clearance be-

tween the front end of the driver

and the needle

is 0 mm be-

cause the front end of the driver

receives the needle to prevent

needle bending. Then, tighten the set screw

securing the driver.

6. Make adjustments so that the clearance (C) in the revolving direction

attains 0.3mm to 0.6mm between the inner hook

and the driver

by bending the inner hook holder block (reverse side of the needle

location block) of the driver

in the direction of the arrow (D).

(Caution) 1. Make sure not to damage the shuttle

race plane

while making adjustment of the driver

.

2. When the driver

is used for a long time, the driver

may be open to increase the clearance. In such

a case, replace it with a new one or adjust the clear-

ance.

7. Loosen the set screw

securing the shuttle

, and adjust the front-

rear position of the shuttle by rotating the shuttle adjusting shaft

so that the clearance between the needle

and the blade point of

the inner hook

becomes 0.05 to 0.1 mm.

8. After adjusting the front-rear position of the shuttle

, set the clear-

ance between the needle

and the shuttle

to 7.5 mm by adjust-

ing the rotating direction, and tighten the set screw

securing the

shuttle.

9. Make positional adjustments for the shuttle upper spring.

Refer to [3.-(43) Adjustment of the shuttle upper spring and lower

thread holder position].

o If the shuttle height of the driver

does not match the tip position

of the needle

, the needle tip

may interfere with the inner hook

and this can be a cause of

needle blunt or wear of the inner

hook

.

o If the engraved lower marker line

of the needle bar

does not

match, this can be a cause of

stitch skipping, thread breakage,

and poorly tense stitch.

o If the clearance is wide between

the needle

and the blade point

of the inner hook, this can be a

cause of thread breakage.

o If there is a clearance between

the shuttle of the driver

and the

needle

, this can be a cause of

needle blunt or wear of the inner

hook

, stitch skipping, and

thread breakage.

o If the clearance in the revolving

direction is too narrow between

the inner hook

and the driver

, this can be a cause of thread

breakage and poorly tense stitch.

If the clearance is too much, there

will be problems of noise, driver

breakage, and wear in the inner

hook race plane.

o If the clearance fails to match

between the needle

and the

shuttle

, this can be a cause of

thread breakage at the sewing

start, defective knotting, and stain

on thread.