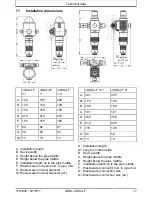

Installation

12

JUDO JUKO-LF

1701430 • 2018/11

3.5

Commissioning

Prior to initial commissioning (or to com-

missioning after maintenance work) fill the

installed device with water and vent:

1.

Open the upstream shut-off valve to fill

the device with water. The device is now

under mains pressure.

2. Attention:

Carry out a backwashing

immediately so that the trapped air can

escape (see chapter 4.2.2)! This pre-

vents damage to the installation by

water hammer pressure surges.

After backwashing, the device is vented

and ready for operation.

4

Operation

4.1

Setting the downstream pres-

sure

To compensate for pressure fluctuations

and to protect the downstream installation,

the downstream pressure can be regulated

via the pressure reducer. The factory pre-

set downstream pressure of 4 bar can be

changed to a value between 1.5 bar and

6 bar depending on the upstream pressure:

1.

Remove the pressure reducer cover

(only for device of connection range

¾" - 1¼").

2.

Undo the countersunk screw on the

handwheel of the pressure reducer.

3.

Turn the handwheel clockwise

(= pressure increase), or turn counter-

clockwise (= pressure reduction).

4.

Open a drawing point behind the device

for a short time. This results in a pres-

sure relief and the set downstream pres-

sure can be read off from the down-

stream pressure gauge.

5.

When the desired downstream pressure

has been reached, retighten the coun-

tersunk screw on the pressure reducer

handwheel to prevent automatic adjust-

ment of the downstream pressure.

6.

Attach the pressure reducer cover again

(only for device of connection range

¾" - 1¼").

4.2

Cleaning of the sieve insert

(backwashing)

A regular cleaning process is necessary to

remove the residues from the sieve fabric

of the device. This process is called

back-

washing

.

Suction pipes are provided for backwash-

ing, which rotate around the sieve fabric

of the fine filter. The backwashing valve

opens on the bottom side of the device.

By reversing the water flow from inside to

outside, deposits on the sieve fabric are

carried away and rinsed out with the back-

wash water. The suction pipes also clean

the inside of the transparent filter bowl with

wiper lips during their movement.

The degree of contamination and cleaning

process can be observed from the outside.

INFO_NO_HEADER

The device is backwashed with

filtered water. The filtered water

supply of the domestic installation

remains intact during the backwash-

ing process. No dirty water can reach

the pure water side during the back-

washing.

4.2.1 Backwashing interval

If cleaning is not performed soon enough,

the result may be damage to the sieve

insert. Large quantities of filtered particles

can deform the sieve fabric and in extreme

case lead to tearing of the sieve fabric.

In addition, larger deposit quantities can