5

139405_A CF

3

BF

3

General Information

This product has been approved to the European

Standard EN 613:2000 and is in accordance with EC Gas

Appliances Directive

2009

/

142

/EC (ex-

90/396

/EEC).

Before installation, ensure that the local distribu-

tion conditions (identification of the type of gas and

pressure) and the adjustment of the appliance are

compatible.

This product, the Jøtul GF

3

BF

3

, may only be used

with Natural Gas G

20

or be converted for the use of

Propane G

31

.

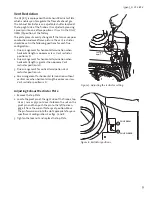

Assembly, installation and maintenance must be

performed by a qualified person in accordance with

the instructions for Assembly, Installation, and Use

enclosed with the product. The installation may only

be operated after it has been inspected by a quali-

fied person and a certificate of completion has been

issued.

The Installation should be carried out in accordance

with the Building Regulations which include the fol-

lowing standards for installation and maintenance

of flues, ventilation and installation of Gas Fires. For

UK BS5440:1, BS5440:2, BS5871 for Republic of Ireland

IS813, ICP3, IS327

The appliance is designed as a freestanding unit and

no additional fixing methods need apply.

This appliance is intended for use on a gas installation

with a governed meter.

Safety Precautions

This appliance must be installed in accordance with the

rules in force. Consult instructions before installation

and use of this appliance.

The appliance is designed as a heating device and all

components will become hot (excluding control knob,

control cover and control switch). Care should be taken

not to touch unit when it is in operation.

WARNING! If you detect an odour of gas:

• Do not light the Stove or any other appliance.

• Do not use electrical switches or the telephone.

• Contact your gas supplier’s emergency number.

The appliance must only be installed and repaired by

qualified personnel. Always turn off the gas supply

before service.

The appliance must be inspected following installation

and at least once a year by qualified personnel.

The appliance must only use gas of the correct type and

pressure. See technical data for more details.

If Propane G

31

is to be used, the appliance must be

converted using the conversion instructions and kit

supplied by Jøtul. This is only to be installed by qualified

personnel.

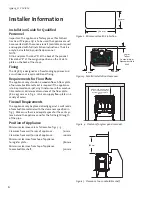

It is permitted to install the appliance against a wall

made of combustible material with the clearances

specified in figs. 5-6.

The minimum clearance to combustible material in

front of the appliance is 6

00

mm.

WARNING:

Curtains may not be placed within 6

00

mm

above the appliance.

Never store combustible gas or liquid in the same room

with the appliance.

WARNING:

Never use the appliance if the front glass

panel has been removed, is cracked, or is open.

Replacement of the glass should be done by a licensed

or qualified service person. Only remove glass for rou-

tine service. Always handle glass carefully.

Do not burn solid fuel in the appliance.

Do not place combustible material on or near the appli-

ance, as the appliance becomes hot.

This appliance becomes hot in use so it advisable to

keep young children, the aged, or infirm, and animals at

a safe distance using a fireguard conforming to BS6

539

or BS

6778

to provide extra protection.