17

139405_A CF

3

BF

3

When There is No Gas Flow

To The Pilot Head

This is the trouble-shooting procedure for the gas supply:

Check if all gas connections are sealed by using strong

soapy water (avoid synthetic soaps). Be certain all valves

from the gas tank/cylinder are fully open.

When the pilot is to be lit for the first time with a

new installation, after a scheduled disconnection or after

the propane tank has been refilled, there will often be

air in the gas tube leading up to the appliance. The tube

system must be cleared of air before the pilot burner can

be lit.

The recommended method for clearing air out of the

tube system, is to push in the gas control knob and turn

anti-clockwise to “PILOT”. Then push in the gas control

knob for 5 seconds and push the control knob on the spark

igniter to the bottom several times. Repeat the procedure

until the pilot is lit.

If the pilot does not light after attempts to clear the

tube system of air, it indicates a problem with the gas

tank/cylinder or a leak in the gas tube. Check the gas pres-

sure as instructed in the section Gas Installation on page

10 and determine if the fault/leak is before or after the

valve on the appliance. If the gas pressure at outlet D (fig.

21) is too low or there is no gas pressure at all, the fault or

leak must be located before the valve on the appliance. If

the gas pressure is OK at outlet (D), but too low at outlet

(E), then the fault or leak must be located after the valve.

Note! SIT valves are always equipped with a fine filter

at the inlet to prevent debris from entering into the valve.

Consequently, a clogged valve is not a common occur-

rence. If gas tubes are dismantled, all gas tubes must be

reinstalled and checked for gas leaks prior to operating

the appliance.

When the Pilot Goes Out - Problems With

the Gas Supply

This is the trouble-shooting procedure for the gas supply:

Remember to push in the gas control knob for at least 30

seconds. Make sure the flame is centred at the thermo-

couple. Make sure the thermocouple is enveloped by the

flame up to at least 3 mm (1/8”) from the tip (fig. 17).

If the flame is abnormally large or small, check the

gas pressure first. See section about gas pressure, page 12.

Then check for errors, dirt or corrosion on the pilot burner

(fig. 17), the pilot orifice and the gas supply to the pilot

burner.

Note! There could be a leak after the valve even if the

pressure is OK at outlet E. You should therefore always

check for leakage.

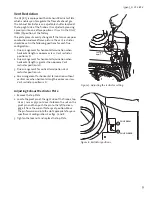

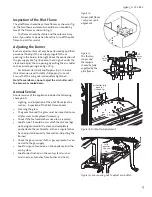

Thermocouple (Fig. 23) and Thermopile

(Fig. 24)

A thermocouple is in principle a thermal generator

and consists of a copper wire (copper-nickel alloy) and an

iron wire twisted together. These wires will create friction

and generate 25 millivolt when exposed to a temperature

difference of 200°C. This voltage is sufficient to make the

gas valve function. In order to produce higher voltage a

thermopile is used, which is based on the same principle

as the thermocouple, but with more copper and iron

wires.

The thermopile produces approximately 500-700

millivolts. This only amounts to 1/3 of the voltage in a

flashlight battery. It is important to understand that even

minor resistance (ohm) will have great impact on such

a small voltage. If resistance is too great, the gas valve

may not receive enough voltage to operate. If there is

too much resistance, the cause may be that the copper

wire conducting the voltage is too long, or there are too

many connections. If the copper wire comes in contact

with metal, it may increase resistance and consequently

reduce the voltage.

When the Pilot Goes Out, But the Gas

Supply is OK.

This is the trouble-shooting procedure for the thermo-

couple, fig. 23,B: Check the copper wire (F) of the thermo-

couple for cracks or damage.

Check the gasket (C) at the valve by loosening the nut

that holds the copper wire. Look for signs of damage, if

the nut has been tightened too hard. A damaged gasket

results in resistance at contact with metal and conse-

quently the voltage to the valve will be too small.

Make sure the flame is centred at the thermocouple.

Make sure the thermocouple is enveloped by the flame

up to at least 3 mm from the tip (see fig. 17). Check the

voltage generated by the thermocouple. Connect the

multimeter (fig.23-E) with plus to the ball point (D) at

the end of the copper wire. Connect minus to the copper

wire. Light the pilot (A) and hold in the control knob to

prevent the flame on the pilot burner from going out. At

this point the multimeter should show 14-28 mV at the

thermocouple.

Note that there are 2 threaded holes that can be used

when installing a new thermocouple. Make sure the blue

wire (A) is fastened at the same threaded hole. The nut

on the thermocouple must not be tightened too much,

just a 1/2 turn. If the gas pressure is correct and the pos-

sible faults above have been checked, the pilot flame can

be adjusted with the adjusting screw. The gas volume is

increased when the screw is turned anti-clockwise.