JOINT MAKING OPERATIONS

The tails of through dovetail joints extend completely through the thickness of the pins on the adjoining

workpiece. In the days before power tools and modern adhesives, skilled craftsmen painstakingly

scribed, hand sawed, and chiseled these joints in the making of furniture, trunks, and all sorts of boxes.

The resulting joints proved mechanically strong and aesthetically pleasing.

Today, through dovetail joints serve primarily as a design element. Several router templates and jigs on

today’s market will make through dovetails, but these cost upwards of $200. With Jointech’s special,

Through-Dovetail Templates, you can now make these beautiful, professional looking joints on your own

router table and only one dovetail bit at one height setting is required!

Although you could make any dovetail a

through joint by excessive surface planing, these templates are

designed to use the smaller angle dovetail bits with long flute lengths to achieve the greater depths of

cut like those made with the very expensive dovetail jigs.

TH ROUG H DOVETAI LS

P

PL

LA

AN

NN

NI

IN

NG

G P

PO

OI

IN

NT

TE

ER

RS

S

Knowing the differences between tails and pins is one of the more important tasks in planning and making

through dovetail joints. Although the plan page illustrations clearly identify them, just remember this; The face

grain of tails looks like a dove’s tail (trapezoid), and the face grain of pins is rectangular.

When working out a dovetail project design, select a template with a dovetail size and spacing to match your

stock thickness. In doing so, don’t forget to plan for an equally sized half-pin at both ends of the joint.

You’ll also need to decide which sides of your project have tails and which sides have pins. If you’re building a

box, such as a jewelry box or even a blanket chest, the front and back pieces should have tails for appearance.

But, if you’re building drawers, the sides should have tails for the strength to survive opening and closing.

Prepare your workpieces. An approximate stock thickness is listed on each template and its full-sized plan. This

will also be the approximate depth of cut. The exact depth of cut must be arrived at by trial and error. Once depth

of cut is determined, the pin boards should then be planed to a thickness that is just slightly less than the height

of the bit. If your pin boards are planed too thin, the result will be small gaps in the corners of each pin after fit-

ted to the tail board. Unless you require thicker stock for the tail boards (which would later require rabbeting),

they should also be surface planed to the same thickness.

Mark your workpieces. To help keep everything straight, gather the four sides of your project and mark each of

the inside and outside surfaces, number each corner, and mark one edge to use as a reference edge to the

fence.

1. Set Depth of Cut

Determine the proper depth of cut following the instructions in the previous

section on Half Blind Dovetails.

2. Prepare Stock Thickness

The method of making through dovetails on a router table requires that your

stock thickness, or at least the pin workpiece, be planed to a thickness that is

slightly less than the height of the bit. Therefore, you must determine the

depth of your cut before preparation of your stock thickness and before

cutting.

Note: The depth of cut can vary by as much as

1

/

16”

per degree

difference in your router bit angle from that called out for on the plan.

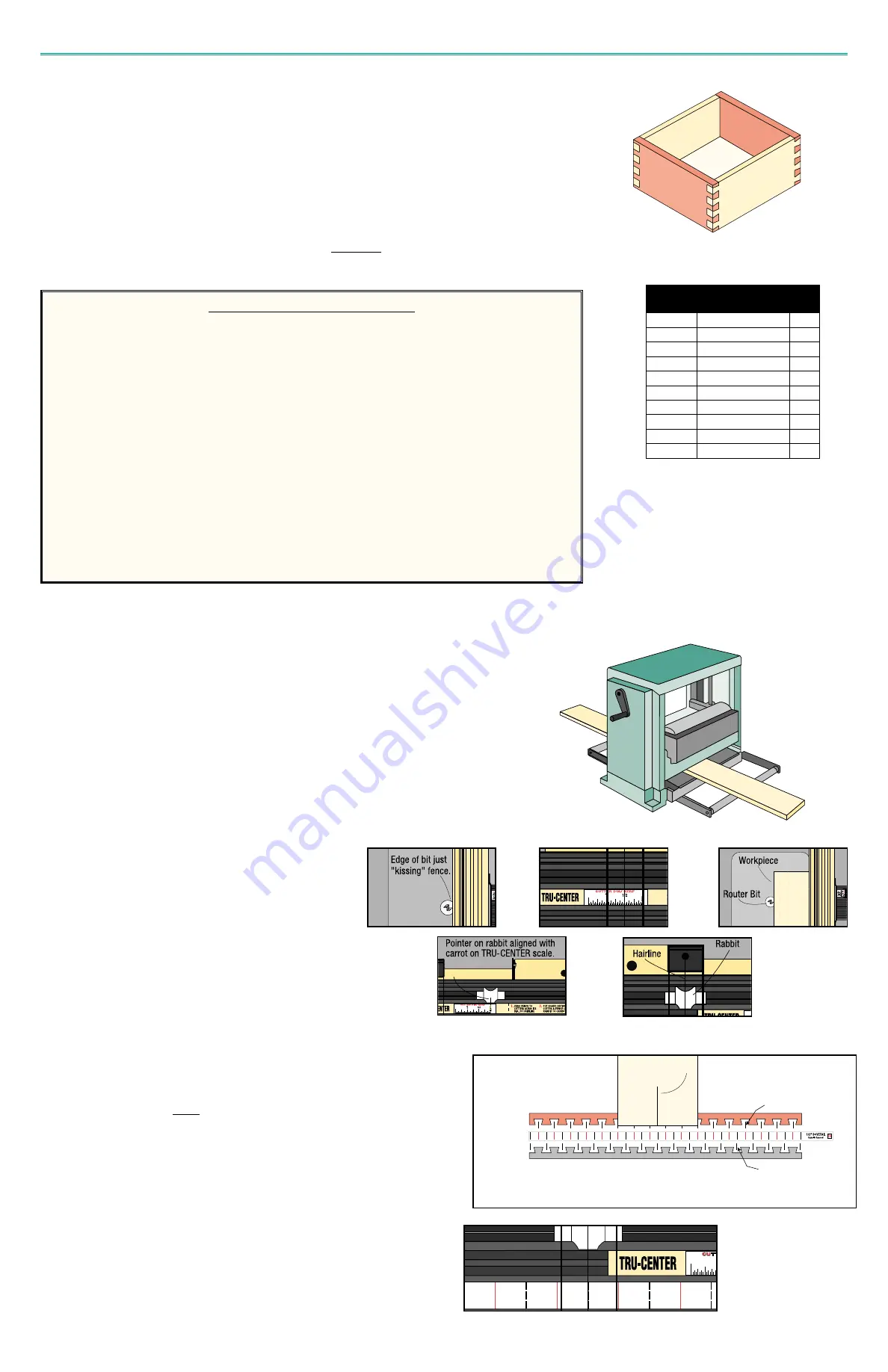

3. Center Board For Symmetry

Use the CLINCHER

Rabbit and the TRU-CENTER scale

to center the bit on your workpiece following the instruc-

tions in the earlier Section on

Making The Perfect Joint.

After finding center, lock carriage and install the selected

template. Take one of your workpieces and place a small

pencil mark at its center on one end. You can do this by

placing it against the fence and up close to the bit. This

center mark will be used in the next step to establish

which series of cuts (RED or BLACK) to use for the pins

and which to use for the tails.

4. Determine Pin and Tail Cuts

Find the full size plan page for your selected template pattern to determine

the choice for a properly cut tail and pin board. Refer to the earlier Section

on

Making The Perfect Joint. Place your board onto plan page and align

pencil mark to one of the lower

symmetry marks. The side of the plans on

which the outer edges of the board overlap grooves will become the series of

tail cuts.

5. Align Template

This example shows the board edges overlapping the grooves on the upper side of plan

(RED). Therefore, for this board width, the tail cuts will be the RED series of cut lines and the

pin cuts will be the BLACK series of cut lines.

With carriage locked and Rabbit still aligned to cursor, adjust the template in

its slot until one of the

symmetry marks you selected is in alignment with the

cursor hairline. Be sure that there will be enough cut lines to the left and

right of cursor to make all the cuts over your board width. You can quickly

verify this by making a comparison of the center mark on your board to the

template and its position under cursor.

Template

Number

Description

1/4",

5/16" Stock

37

44

Plan

Page

3/8",

3/8" Stock

38

45

3/8",

1/2" Stock

39

45

1/2",

1/2" Stock

40

46

1/2",

3/4" Stock

41

46

5/8",

5/8" Stock

43

48

5/8",

3/4" Stock

44

48

5/8",

7/8" Stock

45

49

3/4",

3/4" Stock

46

50

3/4",

7/8" Stock

47

51

1.

2.

3.

5.

4.

16

Pencil Mark at center of board

Upper Symmetry Mark

Lower Symmetry Mark