Installation

Determine location

Read these instructions in their entirety before beginning the installation. For optimum

performance and trouble-free service, it is essential that the installation site meets the location and

space requirements for the model being installed.

Important:

Make sure that the minimum service access space is maintained for cleaning and

maintenance purposes.

The units are designed for outside installation and can be installed at ground level on a suitable

flat level foundation easily capable of supporting the weight of the unit, or on a suitable rooftop

location. In both cases, an adequate supply of air is required. Avoid locations where the sound

output and air discharge from the unit might be objectionable.

The location must be selected for minimum sun exposure and away from boiler flues and other

sources of airborne chemicals that could attack the condenser coils and steel parts of the unit.

If located in an area accessible to unauthorized persons, steps must be taken to prevent access

to the unit by means of a protective fence. This can help to prevent the possibility of vandalism,

accidental damage, or possible harm caused by unauthorized removal of protective guards or

opening panels to expose rotating or high voltage components.

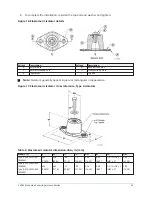

Foundation requirements

Mount units on a flat and level foundation, ground or roof, that can support the entire operating

weight of the equipment. Contact your nearest Johnson Controls Sales Office for shipping and

operating weights.

Ground locations

For ground level locations, the unit must be installed on a suitable flat and level concrete base that

extends to fully support the two side channels of the unit base frame. A one-piece concrete slab

with footings that extend below the frost line is recommended.

The slab must not be tied to the main building foundation because operational noise can telegraph.

Mounting holes (5/8 in.) are provided in the base rails for bolting the unit to its foundation. See

Figure 13 for locations.

For ground installations, precautions must be taken to protect the unit from tampering by or injury

to unauthorized persons. Fasteners on access panels can prevent casual tampering. However,

further safety precautions such as unit enclosure options, a fenced-in enclosure, or locking devices

on the panels may be advisable. Check with local authorities for safety regulations.

Roof locations

Sufficient structure must be provided to safely support the entire operating weight of the unit,

service personnel, and service tooling. Do not damage the roof during installation. If the roof

is of bonded construction, consult a building contractor or architect for special installation

requirements. Use spring isolators to minimize vibration transmission into building structure.

The building must have adequate structural support (by others) at the spring isolator locations.

Typically this is region directly under the side and end base rails of the chiller.

Seismic applications

Avoid installing chillers on springs or roofs where earthquakes are a risk. Springs and roofs amplify

earthquake forces. Rigidly mounting chillers to ground level concrete pads is generally the best

option for earthquake zones. Contact Johnson Controls equipment specialists for help with projects

that have seismic requirements.

YVAM Air-Cooled Centrifugal Liquid Chiller

16