Vacuum testing

About this task:

After the pressure test has been completed, the vacuum test should be conducted as follows:

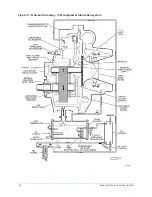

1. Connect a high capacity vacuum pump, with indicator, to the system charging valve as shown

in Figure 14 and start the pump. See

.

2. Open wide all system valves. Be sure all valves to the atmosphere are closed.

3. Operate the vacuum pump in accordance with Figure 14 until a wet bulb temperature of 32°F

or a pressure of 5 mm Hg is reached. See Table 2 for corresponding values of pressure.

4. To improve evacuation circulate hot water (not to exceed 125°F, [51.7ºC]) through the

evaporator and condenser tubes to thoroughly dehydrate the shells. If a source of hot water

is not readily available, a portable water heater should be employed.

Do not use steam.

A

suggested method is to connect a hose between the source of hot water under pressure

and the evaporator head drain connection, out the evaporator vent connection, into the

condenser head drain and out the condenser vent. To avoid the possibility of causing leaks,

the temperature should be brought up slowly so that the tubes and shell are heated evenly.

5. Close the system charging valve and the stop valve between the vacuum indicator and the

vacuum pump. Then disconnect the vacuum pump leaving the vacuum indicator in place.

6. Hold the vacuum obtained in Step 3 in the system for 8 hours; the slightest rise in pressure

indicates a leak or the presence of moisture, or both. If, after 24 hours the wet bulb

temperature in the vacuum indicator has not risen above 40°F (4.4°C) or a pressure of 6.3 mm

Hg, the system may be considered tight.

7. If the vacuum does not hold for 8 hours within the limits specified in Step 6 above, the leak

must be found and repaired.

Note:

Be sure the vacuum indicator is valved off while holding the system vacuum and

be sure to open the valve between the vacuum indicator and the system when checking

the vacuum after the 8 hour period.

Vacuum dehydration

To obtain a sufficiently dry system, the following instructions provide an effective method

for evacuating and dehydrating a system in the field. Although there are several methods of

dehydrating a system, this method produces one of the best results, and affords a means of

obtaining accurate readings as to the extent of dehydration.

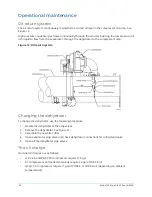

The equipment required to follow this method of dehydration consists of a wet bulb indicator

or vacuum gauge, a chart showing the relation between dew point temperature and pressure in

inches of mercury (vacuum), (see Table 2) and a vacuum pump capable of pumping a suitable

vacuum on the system.

Operation

Dehydration of a refrigerant system can be obtained by this method because the water present

in the system reacts much as a refrigerant would. By pulling down the pressure in the system to a

point where its saturation temperature is considerably below room temperature, heat flows from

the room through the walls of the system and vaporizes the water, allowing a large percentage of it

to be removed by the vacuum pump. The length of time necessary for the dehydration of a system

is dependent on the size or volume of the system, the capacity and efficiency of the vacuum pump,

the room temperature, and the quantity of water present in the system. By the use of the vacuum

indicator as suggested, the test tube is evacuated to the same pressure as the system, and the

distilled water is maintained at the same saturation temperature as any free water in the system.

This temperature can be observed on the thermometer.

33

Model YK Style G R-134a or R-513A