System components description

General

The YORK Model YK centrifugal liquid chiller is completely factory-packaged including the

evaporator, condenser, compressor, motor, lubrication system, OptiView™ control center, and all

interconnecting unit piping and wiring.

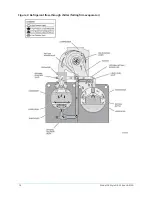

Compressor

The compressor is a single-stage centrifugal type powered by an open-drive electric motor.

The rotor assembly consists of a heat-treated alloy steel drive shaft and impeller shaft with a cast

aluminum, fully shrouded impeller. The impeller is designed for balanced thrust and is dynamically

balanced and over-speed tested. The inserted type journal and thrust bearings are fabricated of

aluminum alloy. Single helical gears with crowned teeth are designed so that more than one tooth

is in contact at all times. Gears are integrally assembled in the compressor rotor support and are

film lubricated. Each gear is individually mounted in its own journal and thrust bearings.

The open-drive compressor shaft seal is a double bellows cartridge style with ceramic internal

and atmospheric seal faces. The seal is oil-flooded at all times and is pressure-lubricated during

operation.

Capacity control

Pre-rotation vanes (PRV) modulate chiller capacity from 100% to as low as 15% of design for normal

air conditioning applications. Operation is by an external, electric PRV actuator which automatically

controls the vane position to maintain a constant leaving chilled liquid temperature.

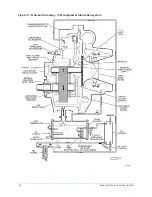

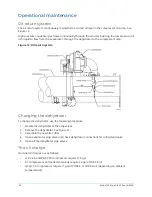

Compressor lubrication system

The chiller lubrication system consists of the oil pump, oil filter, oil cooler and all interconnecting

oil piping and passages. There are main points within the compressor which must be supplied with

forced lubrication as follows:

1. Compressor drive shaft (low speed):

a. Shaft seal.

b. Front and rear journal bearings – one on each side of driving gear.

c. Low speed thrust bearing (forward and reverse).

2. Compressor driven shaft (high speed):

a. Forward and reverse high speed thrust bearing.

b. Two journal bearings.

3. Speed increasing gears:

a. Meshing surfaces of drive and pinion gear teeth.

To provide the required amount of oil, under the necessary pressure to properly lubricate these

parts, a motor driven submersible oil pump is located in a remote oil sump.

When you press the

compressor start

switch on the control center, the oil pump is immediately

energized. After a 50 second pre-lube period, the compressor motor starts. The oil pump continues

to run during the entire operation of the compressor, and for 150 seconds during the compressor

coastdown.

19

Model YK Style G R-134a or R-513A