5750156-UIM-B-0919

Johnson Controls Ducted Systems

9

COMPRESSORS

The compressor used in this product is specifically designed to operate

with R-410A refrigerant and cannot be interchanged.

The compressor uses polyolester oil (POE oil), Mobile 3MA POE. This

oil is extremely hydroscopic, meaning it absorbs water readily. POE oil

can absorb 15 times as much water as other oils designed for HCFC

and CFC refrigerants. If refrigerant circuit is opened, take all necessary

precautions to avoid exposure of the oil to the atmosphere.

POE (polyolester) compressor lubricants are known to cause long term

damage to some synthetic roofing materials.

Procedures which risk oil leakage include, but are not limited to, com-

pressor replacement, repairing refrigerant leaks, and replacing refriger-

ant components such as filter drier, pressure switch, metering device, or

coil.

Units are shipped with compressor mountings, which are factory-

adjusted and ready for operation.

GAS HEAT

These single stage gas-fired heat sections have direct spark ignition.

GAS PIPING

Proper sizing of gas piping depends on the cubic feet per hour of gas

flow required, specific gravity of the gas, and the length of run. National

Fuel Gas Code Z223.1 or CSA B149.1 must be followed in all cases

unless superseded by local codes or gas company requirements. See

Tables 8 and 9.

The BTU content of the gas may differ with locality. Check the value

with the local gas utility.

GAS CONNECTION

The gas supply line must be routed through the 1-5/8 in. hole located on

the right side of the unit. See Figure 3 for the location. The unit is sup-

plied with a rubber grommet that fits in this hole and is used to seal

around the gas pipe. THIS GROMMET MUST BE INSTALLED TO

PREVENT LEAKAGE OF AIR AND WATER INTO THE HEATING/

CONTROLS COMPARTMENT.

Gas piping requirements:

• A drip leg and a ground joint union must be installed in the gas pip-

ing.

• When required by local codes, a manual shut-off valve may have

to be installed outside of the unit.

• Use wrought iron or steel pipe for all gas lines. Apply pipe thread

sealant sparingly to male threads only.

• All piping must be cleaned of dirt and scale by hammering on the

outside of the pipe and blowing out the loose dirt and scale. Before

initial start-up, ensure that all of the gas lines external to the unit

have been purged of air.

• The gas supply must be a separate line and installed in accor-

dance with all applicable safety codes. After the gas connections

have been completed, open the main shut-off valve admitting nor-

mal gas pressure to the gas valve. Check all joints for leaks with

soap solution or other material suitable for the purpose. NEVER

USE AN OPEN FLAME.

CAUTION

This system uses R-410A Refrigerant which operates at higher pres-

sures than R-22. No other refrigerant may be used in this system.

CAUTION

Do not leave the system open to the atmosphere. Unit damage could

occur due to moisture being absorbed by the POE oil in the system.

This type of oil is highly susceptible to moisture absorption.

CAUTION

Exposure to compressor oil, even if immediately cleaned up, may

cause embrittlement (leading to cracking) to occur in one year or

more. When performing any service that may risk exposure of com-

pressor oil to the roof, take precautions to protect roofing.

CAUTION

Do not loosen compressor mounting bolts.

NOTICE

There may be a local gas utility requirement specifying a minimum

diameter for gas piping. All units require a 1/2 in. pipe connection at

the gas valve.

!

!

!

!

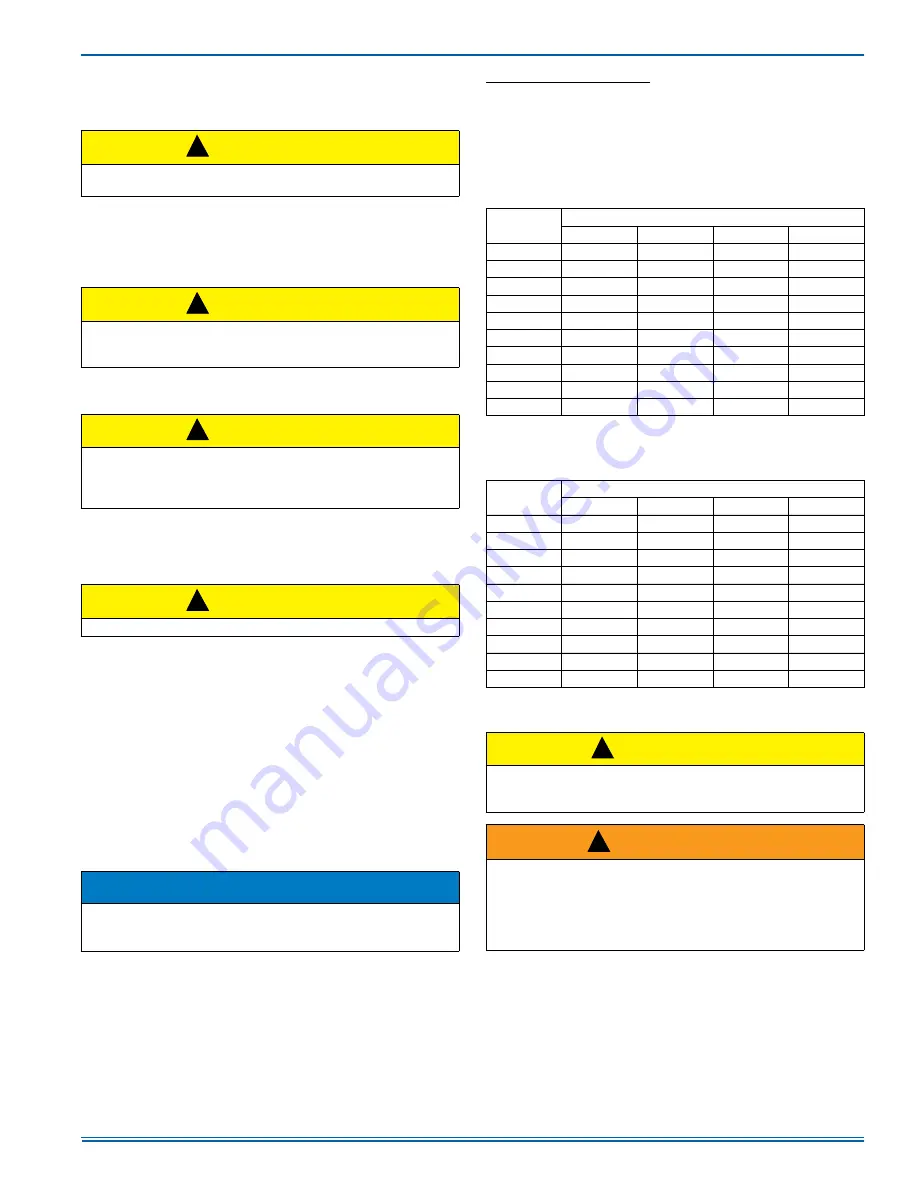

Table 8:

Natural Gas Pipe Sizing Chart

1

1. Maximum capacity of pipe in cubic feet of gas per hour (based upon a pres-

sure drop of 0.3 in. W.C. and 0.6 specific gravity gas).

Length

(ft)

Nominal Inches Iron Pipe Size

1/2 in.

3/4 in.

1 in.

1-1/4 in.

10

132

278

520

1,050

20

92

190

350

730

30

73

152

285

590

40

63

130

245

500

50

56

115

215

440

60

50

105

195

400

70

46

96

180

370

80

43

90

170

350

90

40

84

160

320

100

38

79

150

305

Table 9:

Propane (LP) Gas Pipe Sizing Chart

1

1. Maximum capacity of pipe in thousands of BTU per hour (based upon a

pressure drop of 0.5 in. W.C.).

Length

(ft)

Nominal Inches Iron Pipe Size

1/2 in.

3/4 in.

1 in.

1-1/4 in.

10

275

567

1071

2,205

20

189

393

732

1496

30

152

315

590

1212

40

129

267

504

1039

50

114

237

448

913

60

103

217

409

834

70

96

196

378

771

80

89

185

346

724

90

83

173

322

677

100

78

162

307

630

CAUTION

If flexible stainless steel tubing is allowed by the authority having

jurisdiction, wrought iron or steel pipe must be installed at the gas

valve and extend a minimum of two (2) in. outside of the unit casing.

WARNING

Natural gas may contain some propane. Propane being an excellent

solvent, will quickly dissolve white lead or most standard commercial

compounds. Therefore, a special pipe thread sealant must be

applied when wrought iron or steel pipe is used. Shellac base com-

pounds such as gaskoloc or stalastic, and compounds such as Rec-

torseal # 5, Clyde’s or John Crane may be used.

!

!