RXF ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.410-IOM (JAN 12)

Page 7

NOTE: Care must be taken when entering the unit to

ensure that the nitrogen charge is safely released.

Holding charge shipping gauges on

separator and external oil cooler are

rated for 30 PSIG and are for check-

ing the shipping charge only. They must be removed

before pressure testing the system and before charging

the system with refrigerant. Failure to remove these

gauges may result in catastrophic failure of the gauge and

uncontrolled release of refrigerant resulting in serious

injury or death.

All units must be kept in a clean, dry location to prevent

corrosion damage. Reasonable consideration must be given

to proper care for the solid-state components of the mi-

croprocessor.

Units which will be stored for more than two months must

have the nitrogen charge checked periodically. Contact

Johnson Controls-Frick for long term storage procedure.

COMPRESSOR OIL

DO NOT MIX OILS of different

brands, manufacturers, or types.

Mixing of oils may cause excessive

oil foaming, nuisance oil level cutouts, oil pressure loss,

gas or oil leakage and catastrophic compressor failure.

NOTE: The oil charge shipped with the unit is the best

suited lubricant for the conditions specified at the time

of purchase. If there is any doubt due to the refrigerant,

operating pressures, or temperatures; refer to Frick pub-

lication 160-802 SPC for guidance.

OIL CHARGE

The normal charging level is midway in the top sight

glass located midway along the oil separator shell.

Normal

operat ing level is between the top sight glass and bottom

sight glass. Oil charge quantities are as follows:

BASIC

ADDITIONAL FOR

RXF

CHARGE

OIL COOLER

MODEL

(gallon)

(gallon)

12 – 19

10

1

24 – 50

11

1

58, 68

25

3½

85, 101

36

3½

Add oil by attaching the end of a suitable pressure type

hose to the oil drain valve, located under the oil separator.

Using a pressure-type pump and the recommended Frick

®

oil, open the drain valve and pump oil into the separator.

NOTE: Evacuation of the oil separator will assist the flow

of oil into the unit. Also, fill slowly because oil will fill up

in the separator faster than it shows in the sight glass.

Oil distillers and similar equipment which trap oil must be

filled prior to unit operation to normal design outlet levels.

The same pump used to charge the unit may be used for

filling these auxiliary oil reservoirs.

The sight glass located near the bottom of the separator shell

at the discharge end should remain empty when the unit is

in operation. The presence of oil in this end of the vessel

during operation indicates liquid carryover or malfunc tion

of the oil return.

OIL HEATER

Standard units are equipped with 500 watt oil heaters, which

provide sufficient heat to maintain the oil tempera ture for

most indoor applications during shutdown cycles and to

permit safe start-up. RXF 12–50 use one heater while mod-

els 58–101 use two. Should additional heating capacity be

required because of an unusual environmental condition,

contact Johnson Controls-Frick. The heater is energized only

when the unit is not in operation.

Do not energize the heater when there

is no oil in the unit, otherwise the

heater will burn out. The oil heater

will be energized whenever 120 volt control power is applied

to the unit and the compressor is not running, unless the

16 amp circuit breaker in micro enclosure is turned off (or

15 amp fuse (1FU) in the Plus panel is removed).

OIL FILTER(S)

Use of filter elements other than

Frick may cause warranty claim to

be denied.

The oil filter(s) and coalescer filter element(s) shipped with

the unit are best suited to ensure proper filtration and op-

eration of the system.

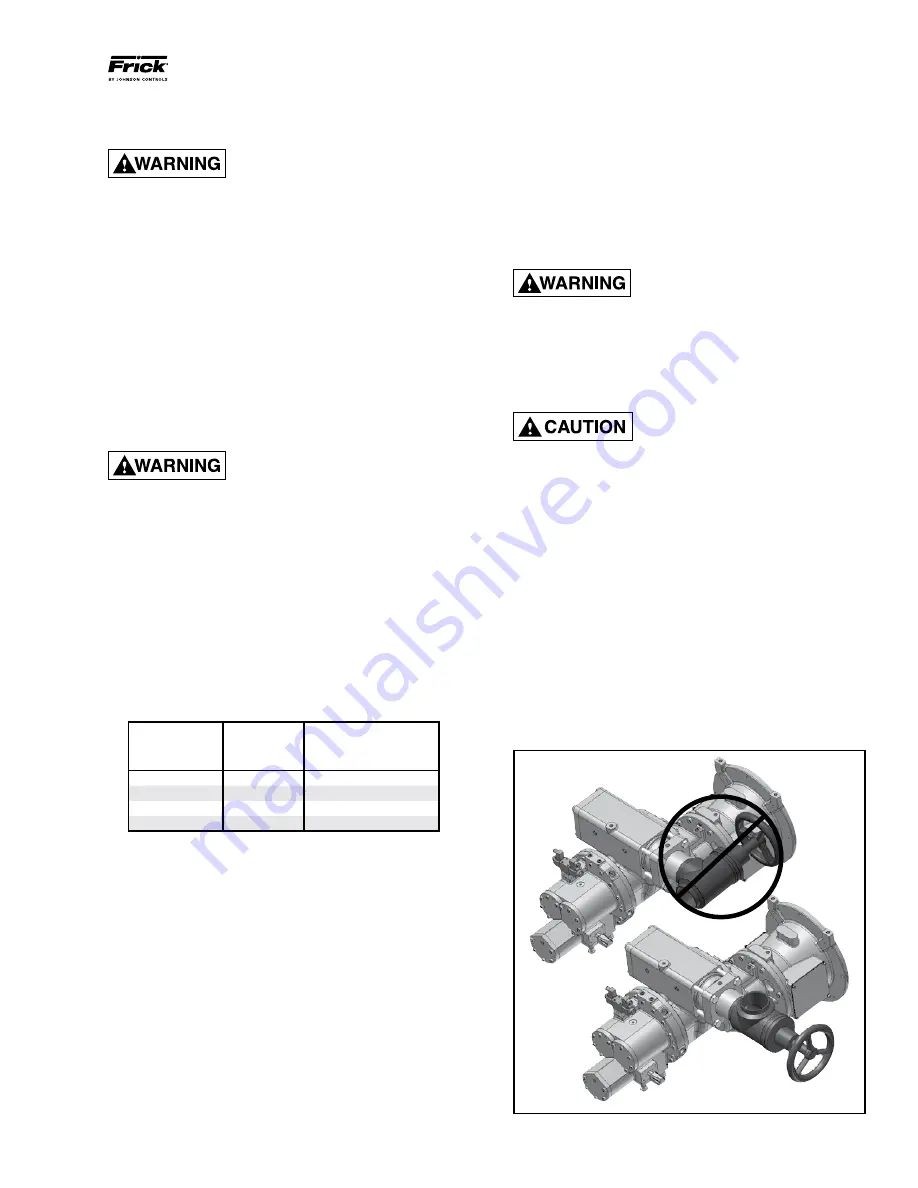

SUCTION ISOLATION VALVE MOUNTING

The suction isolation valve is shipped loose from the factory,

so it can be installed at various positions within the suction

line piping to the compressor.

DO NOT INSTALL

the valve at

the compressor suction with flow

against the cone/button

(see Figure 3 TOP). When the isolation valve is installed in

this position, uneven flow is generated across the suction

check valve which is mounted at the inlet to the compressor.

This uneven flow causes the disks in the check valve to strike

against the stop pin, and eventually damage the internals

of the check valve. If the isolation valve is mounted at the

compressor suction,

DO INSTALL

with flow

across the cone/

button

(see Figure 3 BOTTOM). Please design your system

piping accordingly.

INCORRECT!

CORRECT!

Figure 3 - Suction Isolation Valve Mounting