AD-1272 Advanced Thermal Dispersion Probe Airflow Measuring System Technical Bulletin

11

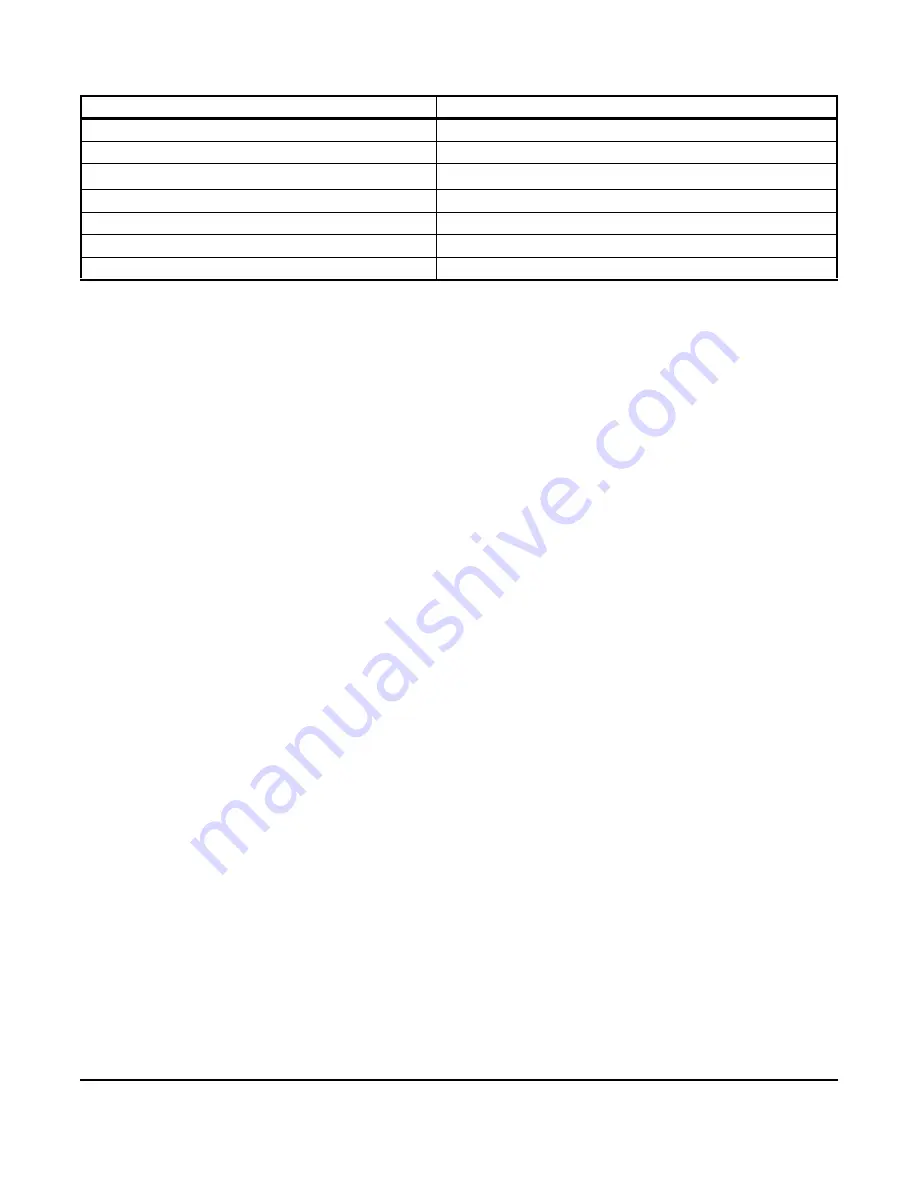

Actual Cubic Meters Per Hour

ACMH

Standard Cubic Feet Per Second

SCFS

Standard Cubic Feet Per Minute

1

SCFM

Standard Cubic Feet Per Hour

SCFH

Standard Liters Per Second

SLPS

Standard Liters Per Minute

SLPM

Standard Cubic Meters Per Hour

SCMH

1.

The standard conditions for Standard Cubic Feet Per Minute airflow measurements are as follows: 14.696 pounds per

square inch (psi) equals 101.325 kPa at sea level. 70 degrees Fahrenheit equals 21.1 degrees Celsius. 50% relative

humidity (RH).

Table 4: Volumetric Units of Measurement (Part 2 of 2)

Volumetric Units of Measurement

Display