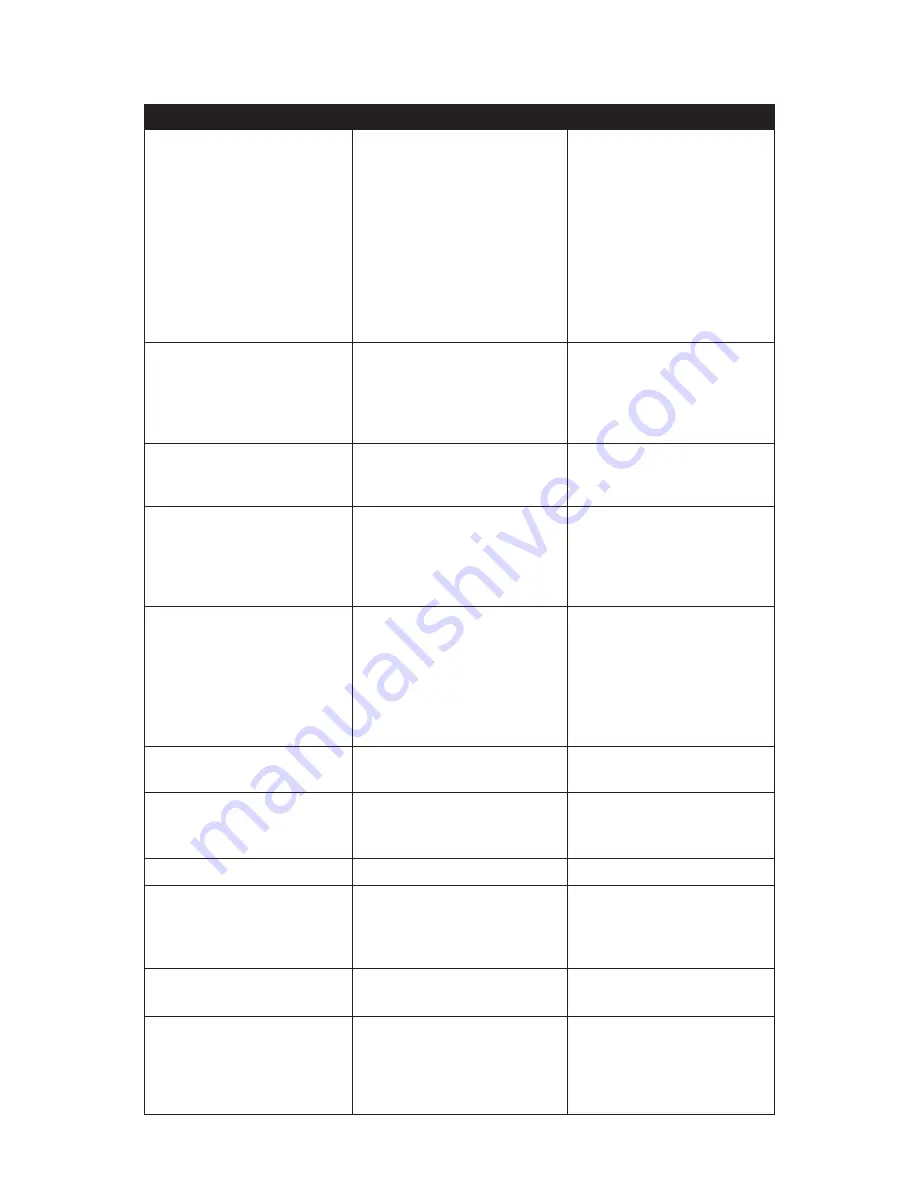

SECTION THREE: TROUBLE-SHOOTING

Solution

1. Open all drain valves

2. Clean float switch

3. Remove thumb knobs and

push engine compartment

cover back a few inches

4. Unkink hose

5. Tighten pump’s garden

hose swivel fitting or replace

impeller

6. Clean filters

7. Replace

1. Turn water on

2. Open all valves

3. Unkink hose

4. Clean or replace

1. See above section “Recov-

ery tank will not drain”

2. Increase defoamer injection

1. Plug in

2. Reset circuit breaker

3. Call us

1. Remove and clean

2. Remove spray jet from

prespray wand and run vinegar

or acid rinse through system

3. Replace injector

4. Clean filter

1. Replace injector or O rings

1. Reseat quick connect

2. Remove and clean

1. Quit using them

1. Clean air filter

2. Clean vacuum shoe

3. Replace worn gasket(s)

1. Immediately stop operating

and call us

1. Clean tube

2. Clean plunger (see Repair

Manual)

3. Replace push button

4. Replace solenoid

Problem

Recovery tank

will not drain

No water supply

RPM’s of vacuum motor

going dramatically down

Vacuum motor will not

turn on

No chemical injection

with prespray

Back filling of

prespray bottle

Water going to machine

but not to prespray system

Hazing of view windows

Slow drying times

Machine shocks you

Defoamer not injecting

Cause

1. Closed drain valve(s)

2. Dirty float switch

3. Hot pump

4. Kinked drain hose

5. Pump not priming

6. Clogged water filters

7. Bad pump or float switch

1. Water not turned on

2. Closed valve(s)

3. Kinked hose

4. Clogged garden hose screen

washer (see figure 27)

1. Recovery tank full of water

2. Excess soap residue in carpet

1. Check wall plug and plug on

back of machine

2. Check circuit breaker

3. Bad switch, loose wire or bad

motor

1. Clogged injector or injector tip

2. Chemical residue in system

3. Worn or pitted injector (check

chemical being used)

4. Clogged chemical line filter

1. Worn Orings in chemical

injector

1. Quick connect not seated

properly

2. Clogged injector

1. Use of strong solvents

1. Obstructed air filter

2. Obstructed vacuum shoe

3. Worn gaskets (you should

hear sucking noises)

1. Short or improper ground in

either machine or outlet

1. Clogged defoamer inlet tube

2. Clogged defoamer solenoid

plunger

3. Broken push button

4. Broken solenoid

-10-

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com