SECTION 3 - MACHINE OPERATION

LIFTPOD by JLG

1001070465

3-5

Getting Started

The following control conditions must be met before the machine

can be operated from the platform controls:

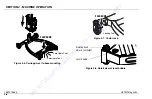

• Batteries must contain enough voltage to operate. Low

battery warning on battery test panel indicates the need to

charge the batteries.

Batteries should be charged for 24

hours prior to first use.

• Emergency stop switch on optional powerpack must be in

the

RESET

position (out).

• Both platform swing-in entry gates must be closed.

Assembly of the Machine

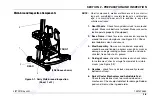

The JLG LiftPod is a user assembled machine. There are three

basic parts that need to be assembled for operation. These parts

are the Base Frame

1

, Carriage/Mast Assembly

2

, and the Plat-

form

3.

Optional parts include the Powerpack

4

, and the Tool Tray

5

DO NOT ATTEMPT TO ASSEMBLE OR USE A MAST ONTO A BASE FOR

WHICH IT IS NOT INTENDED. EACH MAST HAS A "V" SHAPED GROOVE

ALONG ITS LENGTH, WHICH WILL FIT WITHIN THE GROOVE ON A BASE

STUMP FOR WHICH IT IS INTENDED. ALWAYS ENSURE THE MAST IS

FULLY INSERTED ONTO THE BASE STUMP PRIOR TO OPERATION.

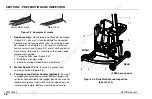

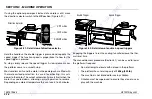

1.

Position the base frame on a firm, level, uniform, sup-

porting surface.

2.

Push down on the base frame’s step plate until the

swivel castor retracts and the base sits on the adjustable

feet (Figure 3-6.). The machine now rests on the two rear

wheels, and the two adjustable feet at the front.

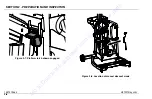

3.

For the FS60 machine’s base (the 30FS base module),

lock the castor wheels (Figure 3-7.).

CRUSH HAZARD - KEEP FEET CLEAR OF ADJUSTABLE FEET AND

UNDERNEATH BASE WHEN STEPPING ON BASE TO RETRACT CASTOR.

4.

Turn the adjustable feet until the level bubble is centred

DO NOT USE THE MACHINE IF THE BASE CAN NOT BE LEVELLED.

Go to Discount-Equipment.com

to order your parts