SECTION 3 - COMPONENT SERVICING

3-6

31215861

THE MAST CONTAINS A GAS CHARGED CYLINDER UNDER CONSTANT PRES

-

SURE. WHEN THE PLATFORM IS FULLY LOWERED THE GAS IS UNDER THE

MOST PRESSURE.

DO NOT RELEASE THE FLYWHEEL CRANK WITHOUT WEIGHT IN THE PLATFORM

DUE TO THE CONSTANT PRESSURE OF THE GAS CYLINDER.

IF REMOVING THE MAST ASSEMBLY FROM THE MACHINE, THE GAS MUST BE

RELIEVED FROM THE PRESSURIZED GAS CYLINDER.

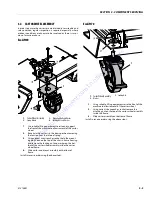

Mast Disassembly

The mast assembly can be disassembled while on the machine

or removed completely from the machine and disassembled.

1.

Remove the tool tray from the top of the mast assem

-

bly.

2.

Remove the frame cover from the base frame.

(See

NOTE:

Be sure to have provisions to refill the gas cylinder once

mast is reassembled.

3.

Remove the mast top cover and using the valve on the

top of the gas cylinder, allow all the gas to escape

from the cylinder.

4.

Remove the platform from the mast.

(See Section 3.6).

5.

Remove the mast from the base frame. If disassem

-

bling off the machine.

6.

Remove the flywheel crank cover from the flywheel

crank.

7.

Remove the mast top cap.

8.

With the gas cylinder de-pressurized, loosen,

but do

not remove,

the four bolts attaching the gas cylinder

mount to the top of the outer mast section.

9.

Check that the mount can be moved up and down by

hand, and there is not a great amount of pressure on

the mount from the gas cylinder. If OK, remove the

bolts from the mount and remove the mount from the

top of the mast.

10.

Remove the safety interlock pin cover and pull the

interlock pin out and rotate 90° to lock the pin in the

retracted position.

11.

Remove the outer mast/front cover assembly from the

mast.

a.

Remove the 14 screws (7 each side) from the

front cover assembly.

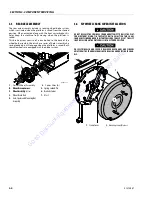

12.

The belt drive system clamp assembly which clamps

the belt ends, is anchored to the inner mast section

and must be unbolted.

a.

The head of the belt clamp mounting bolts must

first be aligned with the access hole in the fly

-

wheel mounting plate on the front of the mast.

This is so they can be kept from turning while

removing the nuts inside the inner mast section.

b.

At the top of the mast assembly approximately 6

in. down on the inside of the inner mast weld

-

ment, remove the two lock nuts attaching the

belt clamp assembly to the inner mast weldment.

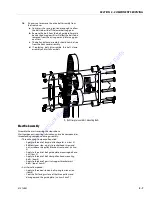

13.

Once step 8 and 9 are completed the complete outer

mast front cover and flywheel assembly can be lifted

off the mast assembly for further disassembly, if

required.

14.

Remove the mast guide roller from the bottom front

of the mast assembly.

15.

Using an assistant, lift the outer mast section off the

inner mast section and set aside for disassembly, if

necessary.

16.

If necessary, remove the gas cylinder from the inner

mast section. If tight in the mounting hole on the bot

-

tom of the inner mast section, you may have to tap

the cylinder rod with a flat punch to get it started out

of the mounting hole.

17.

At the top of the inner mast section carefully pull the

gas cylinder out of the inner mast section.

1.

Top Cover

2.

Mounting Screws

1.

Flywheel Plate Access Hole

2.

Belt Clamp Mounting Bolts

NOTE:

Extend or retract mast assembly to almost stowed position to align with belt

clamp bolt heads.

1

Go to

Discount-Equipment.com

to

order your

parts