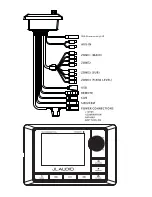

Mounting and Installation

The diagram below shows a typical mounting procedure into a fiberglass panel.

Always follow proper safety procedures. Wear eye-protection at all times with

a dust mask and gloves when cutting.

A mounting template is included to aid in

measuring and marking the mounting surface before cutting or drilling.

Before drilling or cutting, make sure there is adequate space behind the

mounting surface to fit the MM100s, including its wire harness.

1.

Press along the perforation to remove the center section of the mounting

template. (Discard the center section.) The template can be used to verify

there is sufficient flat surface area for mounting and as a guide for cutting the

opening. Tape the template to the mounting location and mark the surface for

cutting the opening and drilling pilot holes.

2.

Use a jigsaw or rotary tool to cut an opening in the mounting surface. If

necessary, use a file or sandpaper to adjust the opening for proper fitment and

smooth the edges.

3.

Place the MM100s into the opening and check that the mounting holes remain

aligned with the pilot hole marks taken from the template. If not, adjust and

mark new holes as necessary.

4.

Remove the MM100s and drill four (4) pilot holes in the mounting surface at the

pilot hole marks.

5.

Peel the adhesive backing from the mounting gasket and affix to the rear of the

bezel. Connect all wiring and place the MM100s into the opening.

6.

Secure the MM100s using the four (4) stainless steel screws. Press the trim ring

onto the front of the MM100s.

Power Connections

The 4-pin plug with wire leads is used to make power related connections. Make

sure to carefully plan the wiring of your system prior to routing wires and making

connections. Refer to the table on the next page when making power connections.

Summary of Contents for MediaMaster 100s

Page 6: ...0 0 UHFHLYHU RQO 17...