3

Filtered water

We recommend the ins-

tallation of a manual

control valve in the out-

let of the filtration sta-

tion to make maintenan-

ce easier.

Drainage

Drainage water coming

out from the backwash

hydraulic valves is

collected in a common

HDPE manifold.

The drainage must be at

height 0. If installation

requires a higher level,

then the difference in

meters translated to

pressure units must be

added to the minimum

recommended backwash

pressure (2,5 bar).

Our range has different filtration degree color-coded

discs depending on the total suspended solids of raw wa-

ter to be filtered and our automatic filtration stations are

designed to match flow requirements of the installation.

The cartridge spine has an internal piston spring for com-

pressing or releasing the discs during the filtration and

backwash cycles.

Filtration Mode:

During the filtration process the filter discs are tightly

compressed together by the spring and the differential

pressure, forcing the water to flow through the grooves

of the discs.

Backwash Mode:

During the backwash process, the discs are released. At

the same time, the multi-jet nozzles present in the three

internal manifolds of the cartridge spine sprays clean wa-

ter tangentially causing the discs to spin and forcing the

retained solids out to the drainage outlet.

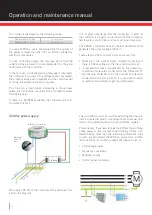

In filtration position

In cleaning position

1. The piston compresses the disc cartridge.

2. The conical flexible non-return membrane remains

open, allowing filtered water to go to the network.

1. The backwash valve inverts clean water flow into the

filter, closing the conical flexible non-return membra-

ne. This forces clean water through the three spine

manifolds that spray out tangentially the dirtiness from

the discs.

2. At the same time, the upper piston is compressed by

incoming pressure through the spine manifolds, relea-

sing the discs that spin in a centrifugal movement at

high speed.