20

3

FINAL ASSEMBLY INSTRUCIONS

INSTRUCIONS FOR AUTHORIZED PERSONS ONLY

Before installation

The safety instructions must be read carefully before installation. You must definitely fulfil the requirements stated

by the uwe company and by the standars authorities. If the instructions are not observed, the installation engineer

shall bear the sole responsibility. The manufacturer shall thus be absolved of any liability.

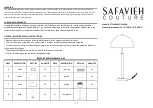

Installing the nozzle assembly (fig.1)

1.

Unscrew gland nut (10) and remove blank plastic washer. Leave rubber sealing washer (13) in housing.

2.

Thread free end of the 10 m length of PVC pneumatic tube (12) through the gland aperture from within the pool.

3.

On the pneumatic switch assembly (3) is a short length of pneumatic tube (12). Thread this through the gland

nut (10) and fix it to end of the tube connector (11) showing inside the pool. Tighten gland nut (10).

4.

Insert 5 disks from white plastic disk (9) on the ground of the jet-casing (15). After that insert seal (8) and one

of the clamping disk (7) inside. Then put down the nozzle (6) and the clamping disk (5). The clamping disk (5)

is fortified on the nozzle with 4 screws (4). If the nozzle wouldn’t be steered into several directions you have to

put out 1 of the plastic disk (9)

5.

The face plate (2) will be attract with the 2 Screws (1) easily.

Installing the pump, suction and pressure hoses with PVC-fittings

If the pump is to be installed on a console/mounting bracket, supplied as an optional extra, it should be fitted to

the pool wall beforehand with concrete wall fixings. The pump should be secured with anti-vibration mountings.

Alternatively, the pump should be secured with appropriate fixings on a concrete plinth. Stick the suction - and

pressure hose with „TANGIT “into the transition joint of the wallfitting. After the splicing, the ball-valves should be

open and closed like picture 4.

Important: be careful if you stuck together suction - and pressure hose correctly. (Arrow on the

ball-valves signed on Picture 4).

Do not forget to insert the gasket between hose nipple and pump nipple.

Tighten the pump base with fixing bolts or anti-vibration mountings.

Important note:

The pump is normally installed in the walkway behind the pool wall.

The installation evironment must be dry and must be protected by a suitably sized floor drain

to prevent flooding.

Installing the air inlet fittings (fig.5

Insert the non return valve into the end of the air inlet tube. Fix the clip (17 to the pool wall in such a way that the

opening of the air inlet fitting (16 is at least 5 cm above the maximum water level of the pool. Push the tube over

the straight connector of the valve. Secure the tube with the pipe clamp.

Note:

The purpose of the non return valve is to absorb back pressure generated by use of the massage

attachments, and to prevent water spraying out of the air inlet fitting. The valve will only function

properly as long as no hair/debris or lime deposit accumulates within it.

Therefore the valve has to be fixed above water level.

Shorten the air inlet tube if it is longer as necessary. The shorter the tube, the lesser the resistance and the higher

the volume of air flow.