15

Basic Operations

Removing the belt guard

exposes more of the sanding belt! Replace the

belt guards immediately after completing any

sanding that requires its removal! Failure to

comply may cause serious injury!

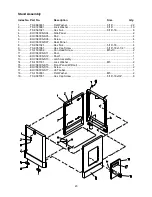

Horizontal Sanding

For

horizontal sanding

, the

platen

is locked in the

horizontal position as shown (F) and the

removable

fence

(D) is secured to the

table

(E) as follows.

Referring to Figure 16:

1. Place

5/16

flat washers

(not shown) and

guide

blocks

(B) on two 12mm

lock knobs

(A) – Note:

the 12mm refers to the threaded shaft length.

2. Insert the

guide blocks

(B) into the

miter slot

(C) and position the

lock knobs

(G) on the

table

(E) as shown.

3. Place the

removable fence

(D) on the table

and secure by tightening the

lock knobs

(G, Fig. 16 and Figure 17).

The

backstop

(H, Fig. 17) can also be used by

swiveling the

drum guard & dust port

(J, Fig. 17)

out of the way and placing the backstop pin in the

positioning hole and securing in place with the

lock

knob

(K, Fig. 17) and 5/16"

flat washer

.

Note:

This

is better shown in Figure 18. The

drum guard &

dust port

(J, Fig. 17) can then be returned to the

position shown.

Vertical Sanding

Referring to Figure 18:

For

vertical sanding

, the

platen

(G) is locked in the

vertical position as shown and the

backstop

(H)

and/or the

miter gauge

(B) may be used.

Miter Gauge

1. Slide

the

guide bar

(D) of the

miter gauge

(A)

into the

miter slot

(C) on the table.

2.

Set the miter angle; then secure the miter by

tightening the

lock handle

(B).

Backstop

Place the backstop pin in the positioning hole and

secure in place with the

lock knob

(E) and 5/16"

flat washer

(F).

Figure 16

Figure 17

Figure 18

Summary of Contents for OES-80CS

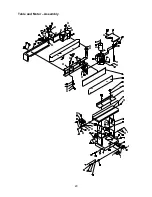

Page 20: ...20 Table and Motor Assembly...

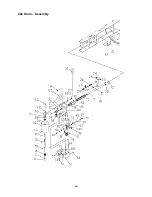

Page 22: ...22 Idle Drum Assembly...

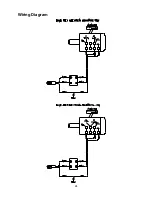

Page 24: ...24 Wiring Diagram...