8

Assembly

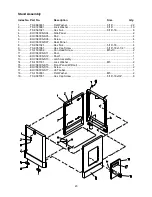

Stand Assembly

Referring to Figure 1:

1. Remove all contents from the shipping

container.

2. Clean all rust protected surfaces with a mild

solvent. Do not use paint or lacquer thinner,

gasoline, or mineral spirits; these will damage

painted surfaces.

3. Attach

the

four

rubber pads

(A) to the bottoms

of the

side panels

(C) with four each

5/16” x 5/8”

screws

, 5/16”

flat washers

and

5/16”

hex nuts

(B). The hardware can be found

in the bag with the rubber pads.

4. Attach

the

side panels

(C) to the

front panel

(D)

with four 5/16” x 5/8”

hex cap screws

, eight

5/16”

flat washers

, four 5/16”

lock washers

, and

four

5/16”

hex nuts

(E). Hand tighten the

hardware at this point.

Note:

Assemble the stand upside down to

make sure that the tops of the panels are flush.

5. Mount the

shelf

(F) to the inside of the stand

with two

M5x10

pan head screws

, two M5

flat

washers

and two M5

lock washers

(G).

6. Finish the stand assembly by attaching the

rear

panel

(H) to

side panels

(C) with four

5/16” x 5/8”

hex cap screws

, eight 5/16”

flat

washers

, four 5/16”

lock washers

, and four

5/16”

hex nuts

(J).

7. Make sure stand is sitting evenly on a level

surface before tightening hardware.

Installing Table and Motor Unit to Stand

The Table and Motor Unit is

heavy! Use great care and adequate resources

when lifting the unit up onto the stand! Failure

to comply may cause serious injury and/or

damage to the sander and/or property!

Referring to Figure 2:

1. With the aid of another person, carefully lift the

table and motor unit

(A) out of the shipping

box, and up onto the

stand

(B).

2. Line up threaded holes in the

base

(C) with the

holes in the

stand

(D).

3. Open the

cabinet door

(E) and through the

opening attach main unit to stand with two

5/16” x 1-1/4”

hex cap screws

(F), two 5/16”

lock washers

(G) and two 5/16”

flat

washers

(H). Tighten with a 12mm wrench.

Figure 1

Figure 2

Summary of Contents for OES-80CS

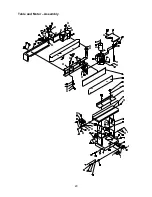

Page 20: ...20 Table and Motor Assembly...

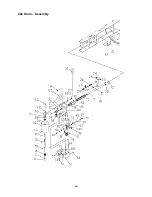

Page 22: ...22 Idle Drum Assembly...

Page 24: ...24 Wiring Diagram...