9

If hardwired:

Permanently connected tools: This tool should be

connected to a grounded metal permanent wiring

system; or to a system having an equipment-

grounding conductor. Make sure a disconnect is

available for the operator. During hard-wiring of the

machine, make sure the fuses have been removed

or the breakers have been tripped in the circuit to

which the drill press will be connected. ALWAYS

FOLLOW PROPER LOCK-OUT/TAG-OUT PRO-

CEDURES.

6.2

Extension cords

The use of extension cords is discouraged; try to

position equipment within reach of the power

source. If an extension cord becomes necessary, be

sure it is heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating.

Table 2 shows recommended size to use depending

on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

Ampere

Rating

Volts

Total length of

cord in feet

More

Than

Not

More

Than

240 50 100

200 300

AWG

0 6

18

16

16 14

6 10

18

16

14 12

10 12

16

16

14 12

12 16

14

12

Not

Recommended

Extension Cord Recommendations

Table 2

7.0

Adjustments

Disconnect machine from

power source before making adjustments,

unless indicated otherwise.

7.1

Blade installation and removal

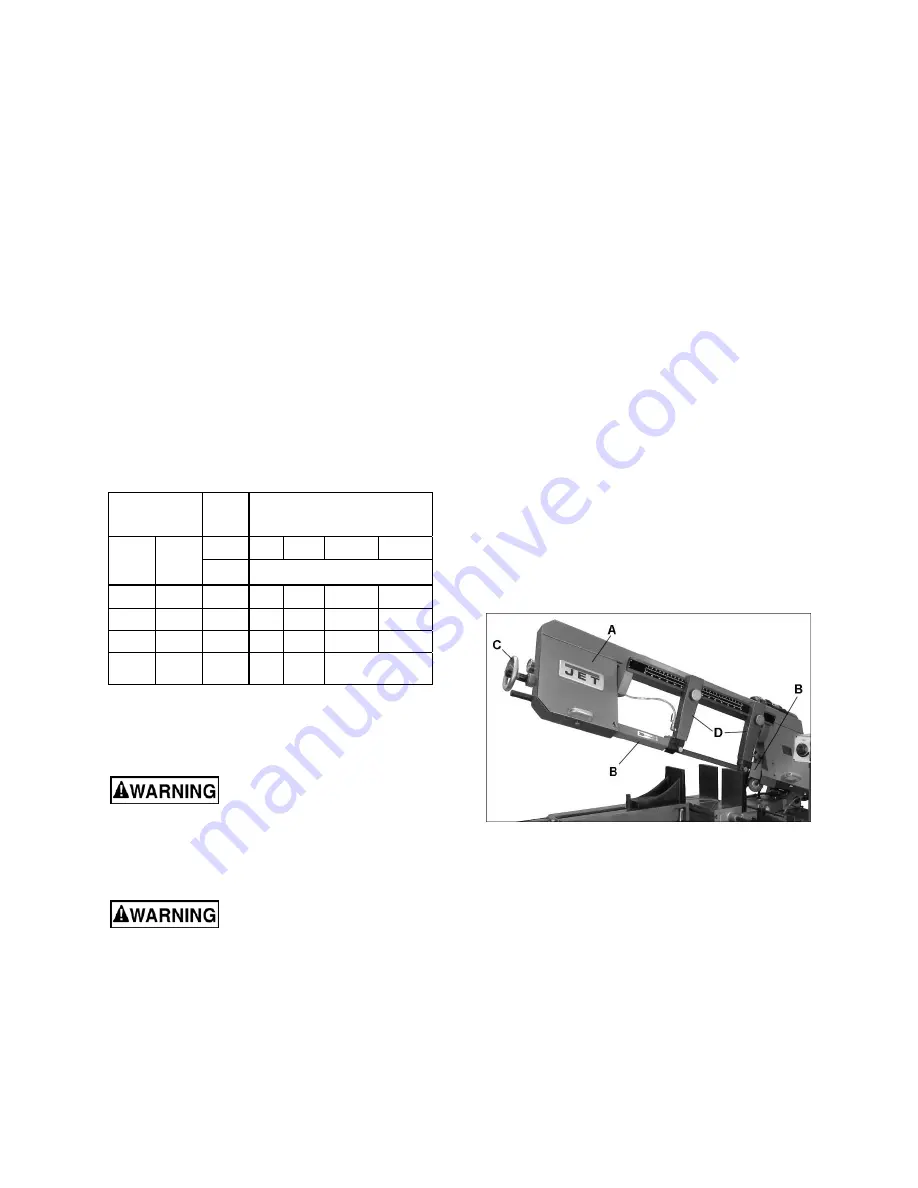

Refer to Figure 7-1.

Always wear leather gloves

when handling blades to avoid injury.

A blade (1-1/4 in. W x 172 in. L) is pre-installed and

tensioned on saw. To replace blade:

1. Raise bow about 15-degrees and keep it in

raised position by turning feed rate control knob

clockwise all the way (see

sect. 8.0

).

2. Disconnect machine from power source.

3. Open both wheel covers (A, Figure 7-1) and

clean out any swarf from wheel areas.

4. Remove red blade guards (B).

5. Back off the blade guides by loosening knob (H,

Figure 7-2). Back off the wire chip brush.

6. Release blade tension by turning blade tension

handwheel (C) counter-clockwise.

7. Remove blade from both wheels and out of

each blade guide.

8. Make sure teeth of new blade are pointing in

direction of travel. If necessary, turn blade

inside out.

9. Position new blade around wheels and through

upper slot. Slide it into blade guide bearings

with back edge of blade contacting backup

bearing. (see Figure 7-2). For further guide

bearing adjustment, see

sect. 7.3

10. Lightly increase tension (C) and position blade

so it rests against shoulder of both wheels.

11. When blade is properly positioned, place full

tension upon it (see

sect. 7.4.1

).

12. Reinstall blade guards (B).

13. Adjust chip brush up against blade teeth.

14. Jog the start/stop buttons to ensure blade is

tracking properly. If tracking adjustment is

needed, see

sect. 7.4.2

.

15. Close wheel covers.

Figure 7-1: blade changing

7.2

Guide post adjustment

The blade guide posts (D, Figure 7-1) must be set

to just clear the workpiece, but should not interfere

with workpiece or other saw components during

bow’s descent.

Loosen knobs and slide posts into position. Always

tighten knobs before operating machine.

7.3

Blade guide adjustment

The bearing and carbide guides come pre-adjusted

from the factory for the installed blade. If adjustment

is needed, or if a blade is replaced, follow the below

steps for left and right guides.