18

Belt Tracking Adjustment

The belt should run at the center of the belt arm

without veering to the left or right. Check this as

follows:

1. Disconnect machine from the power source.

2. Rotate the belt by hand and observe how it

tracks. The belt should run centered on the

belt wheels.

3. If the belt has a tendency to track left or

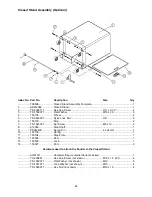

right of center, loosen locking nuts (A,

Figure 28).

4. Turn the front screw (B, Figure 28) while

turning the belt by hand and observe belt

tracking. Once the belt starts to move in the

desired direction, stop and turn the rear

screw (C) in the same manner.

NOTE:

These adjustments are sensitive and should

be done in small increments.

5. Grasp the tensioning adjustment handle (D)

and start the machine. Be ready to pull

down on the tension adjustment handle

should the belt want to run off the belt

wheel.

6. Fine adjustment of the tracking may be

necessary. When the tracking has

stabilized, slowly release the belt tensioning

arm and let the machine run for two

minutes.

7. Tighten lock nuts (A) when tracking

adjustments are satisfactory.

Belt Replacement

1. Disconnect machine from the power source.

2. Remove the lock knob and open the left

side panel.

3. Release belt tension using the handle (D,

Figure 28), and slide belt off the wheels.

4. Refer to “Installing Abrasives” section for

instructions on installing the new belt.

Abrasive Disc Replacement

1. Disconnect machine from the power source.

2. Slowly work the tip of a knife under the

abrasive disc, and work it around the

circumference of the disc until abrasive can

be removed by hand.

3. Clean the aluminum disc of any residual

adhesive, using mineral spirits or similar

solvent. Allow to dry.

4. See “Installing Abrasives” for instructions on

installing the new abrasive disc.

Figure 28

Maintenance

Before doing maintenance on

the machine, disconnect it from the electrical

supply by pulling out the plug or switching

off the main switch! Failure to comply may

cause serious injury.

Wipe the machine down after each use.

Keep exposed metal surfaces clean and rust-

free. A light coat of paste wax applied to the

tables will help protect the surfaces.

Make periodic inspections of the sander,

checking fastener tightness, abrasive wear,

tracking accuracy, etc. Listen for any unusual

motor noises or vibrations that might indicate

bearing fatigue.

(Note: All rotating parts run on sealed ball

bearings and do not require lubrication.)

If you will not be using the machine for an

extended period, remove the abrasive belt; this

will prevent it from stretching and will prolong its

life.

If the power cord is worn, cut, or damaged in any

way, have it replaced immediately.

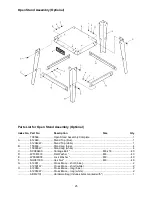

Summary of Contents for JSG-6DC

Page 20: ...20 JSG 6DC Belt Disc Sander Assembly...

Page 26: ...26 Electrical Connections...

Page 27: ...27...