16

Adjust 90° Stop

6. With the table locked at 90°, loosen the hex

nut on the 90° stop, and adjust the set

screw to seat against the stop block. See

Figure 19. Re-tighten hex nut to secure the

setting.

7. If angle indicator adjustment is necessary,

loosen the screw and shift the pointer to

zero, and re-tighten the screw.

Adjust 45° Stop

8. Flip the stop block out of the way, and tilt

the table down to 45°. Verify the setting of

the 45° angle stop (Figure 19). Use the

same procedure as above but with a 45°

measuring device on the table. Correct the

stop as needed.

Belt Arm Orientation

Loosen the belt arm lock screw (see Figure 13)

to tilt the belt arm to vertical or horizontal

position. The belt arm can also be secured at

any angle between. Always tighten the screw

before operating.

Note:

Belt tracking may require re-adjustment if

the belt assembly is moved from vertical to

horizontal or back again.

Limit Screw Adjustment

This set screw (Figure 22) limits the rotation of

the belt arm to vertical and horizontal positions,

and has been pre-set. If it should ever need re-

adjustment:

1. Loosen lock nut on the set screw with a

10mm wrench.

2. With a 3mm hex key, turn set screw all the

way in until it bottoms out. Back screw out

three turns and re-tighten lock nut, while

holding screw in place.

Disc Table Adjustment

1. Disconnect machine from power source.

2. Place a square on the table and against the

disc. See Figure 23. Loosen both lock

knobs, move the table until the square sits

flush to both surfaces at 90°, and re-tighten

both knobs. Note: You may need to pivot

the stop block out of the way.

3. Place a combination square in the miter

gauge slot and check the distance from the

slot to face of the disc. See Figure 24. Slide

the square along the slot to the other side of

the disc and check the distance. The

distances should be equal to ensure that the

miter gauge travels parallel to the disc.

Figure 22

Figure 23

Figure 24

Summary of Contents for JSG-6DC

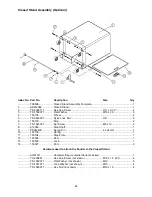

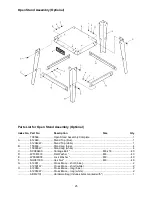

Page 20: ...20 JSG 6DC Belt Disc Sander Assembly...

Page 26: ...26 Electrical Connections...

Page 27: ...27...