8

(2)To tighten the longitudinal feed travel of the table for cross feed

milling,tighten the two small leaf screw on the front of the table base.

(3)Adjustable travel stops are provide on the front of the table for control of

cross travel and the desired milling length.

TO CHANGE TOOLS

(1)

Removing Face Mill or Drill Chuck Arbor

Loosen the arbor bolt at the top of the spindle shaft approximately 2 turns

with a wrench.Rpa the top of the arbor bolt with a mallet.

After taper has been broken loose,holding chuck arbor on hand and turn

detach the arbor bolt with the other hand.

(2)

To install Face Mill or Cutter Arbor

Insert cutter and cutter arbor bolt detach securely, but do not over-tighten.

(3)

Removing Taper Drills

(a)Turn down the arbor bolt and insert the taper drill into the spindle shaft.

(b)Turn the rapid down handle rod down until the oblong hole in the rack

sleeve appears.Line up this hole with the hole in the spindle.Insert key punch key

through holes and strike lightly with a mallet. This will force the taper drill out.

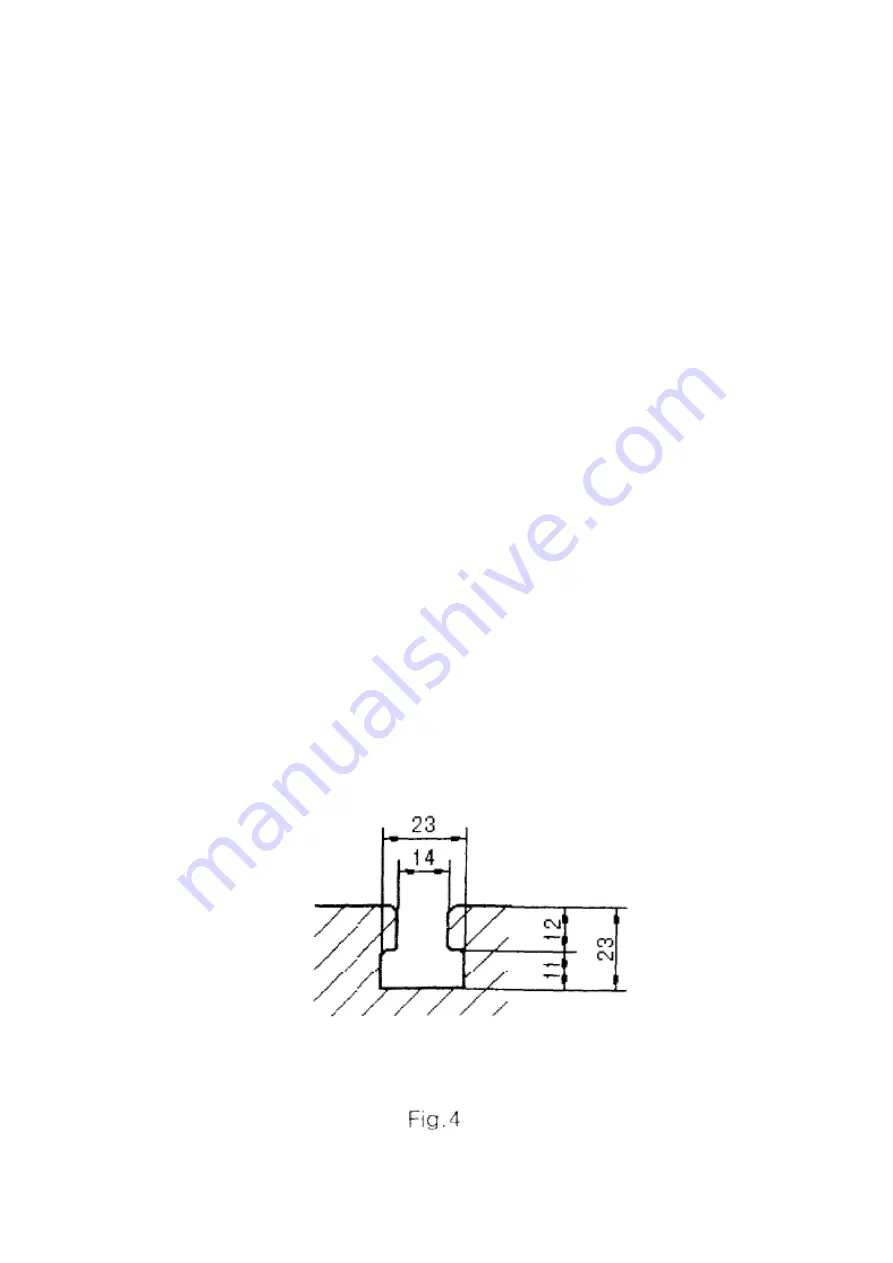

SPECIFICATION OF T-SLOT

The size of T-Solt on table as fig.4