22

12.4

Thread Cutting

Threading is performed in multiple passes, with an

initial cutting depth of about 0.2 mm, and

decreasing depth in succeeding cuts. It is

recommended that test cuts be made on scrap

material and the results checked before proceeding

with regular material.

1. Move

thread selection lever

(F, Figure 31) to

desired direction, for right-hand or left-hand

threads.

NOTE: The overrunning clutch in the

apron will prevent the tool post from feeding

for left-hand threads. It will only feed when

right-hand threads are being cut.

Figure 32

2. Set

speed levers

(E

1

,E

2,

Figure 31) to desired

speed. Use the lowest speed possible when

threading.

3. Select desired thread using

thread pitch

levers

(G

1

,G

2

,G

3

, Figure 31) in conjunction

with the charts on the headstock. These charts

are also included in

section 16.10

of this

manual.

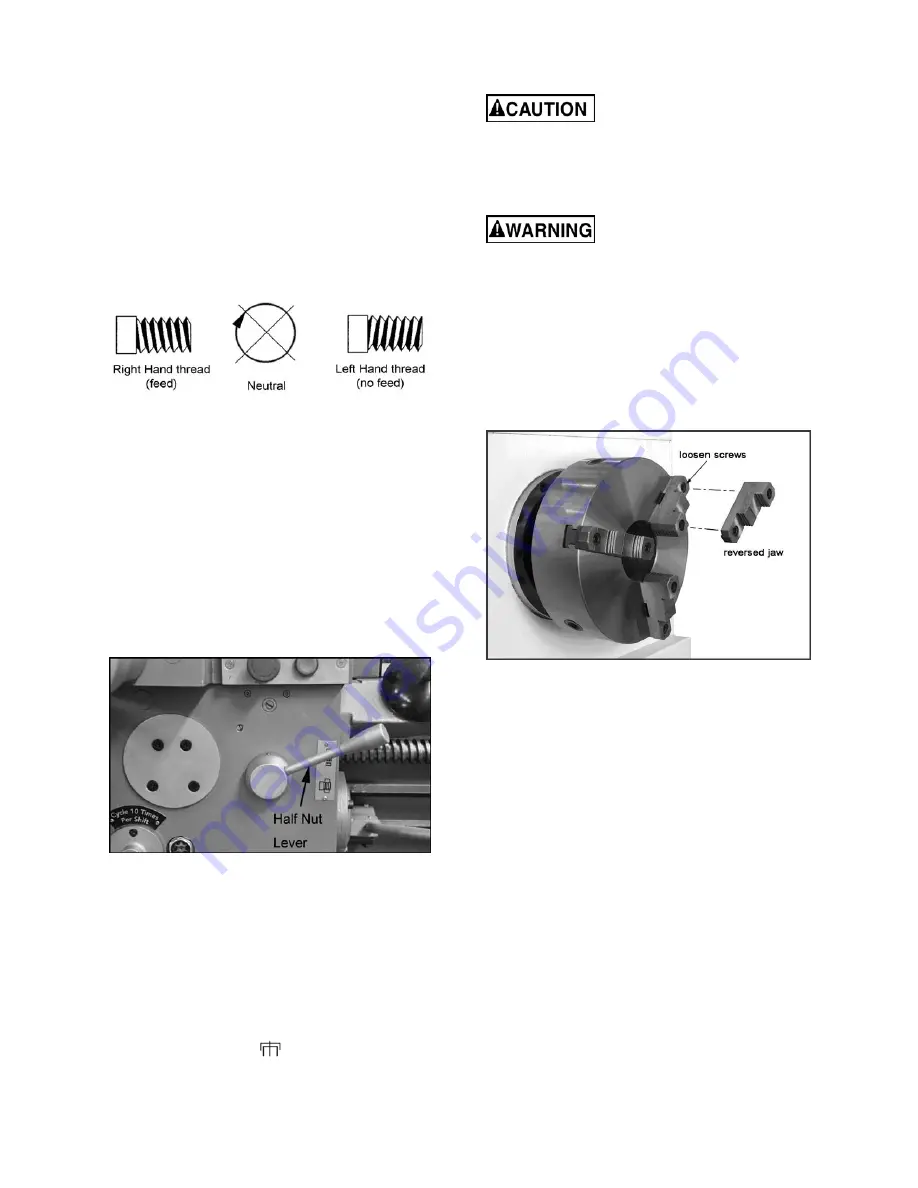

4. Engage the half nut (Figure 33). The half nut

must be engaged during the entire threading

process when doing metric, diametral, and

modular threading.

Figure 33

5. When tool reaches end of cut, disengage and

back out the tool to clear the workpiece.

6. Reverse direction to allow cutting tool to return

to its starting point.

7. Repeat the process until desired result is

obtained.

NOTE:

When a special thread must be cut that is

not found on the chart, move thread change control

lever (G

1

, Figure 31) to

position, and lever (G

3

)

to

IV

, then reset the change gears.

13.0

Adjustments

Adjustments to the lathe,

especially those involving alignments of

bearings, spindle, leadscrew, clutch, etc.,

should only be performed by qualified

personnel, as improper alignments can damage

the machine and/or create a safety hazard.

Turn off main switch and press

emergency stop button before making

adjustments to the lathe.

13.1

Chuck Jaw Reversal

The three jaws on the scroll chuck are reversible,

to hold stock with larger diameters. See Figure 34.

Loosen the two screws with the provided hex key,

remove the jaw, and rotate it 180-degrees. Re-

install the jaw, and tighten each screw in

increments until fully tightened.

Figure 34 – Chuck jaw reversal

13.2

Gib Adjustments

After a period of time, some of the moving

components may need adjustment for play due to

wear.

Do not overtighten gib screws as this can

hasten wear to components.

Saddle

– Turn screws (A, Figure 35) on either side

of the saddle at the rear to adjust drag on the

saddle.

Cross Slide

– Gib screws are located at front and

rear of slide opposite to one another (B, Figure 36).

To adjust drag, loosen rear gib screw one turn, and

tighten front gib screw a quarter turn. Rotate the

handwheel to check the play. Repeat as needed

until slide moves freely without play. Gently tighten

rear gib screw.

Summary of Contents for GH-26120ZH

Page 34: ...34 18 0 Change Gear Diagram Figure 54 ...

Page 35: ...35 This page intentionally left blank ...

Page 40: ...4 1 1 Bed Assembly I Exploded View ...

Page 41: ...5 1 2 Bed Assembly I for 120 ZH only Exploded View ...

Page 44: ...8 2 1 Bed Assembly II Exploded View ...

Page 45: ...9 2 2 Bed Assembly II for 120 ZH only Exploded View ...

Page 48: ...12 3 1 Headstock Assembly I Exploded View Ⅲ Ⅳ Ⅴ Ⅶ Ⅵ Ⅱ Ⅰ Ⅱb Ⅶb ZⅡ ZⅠ ZⅡ ...

Page 51: ...15 4 1 Headstock Assembly II Exploded View ...

Page 54: ...18 5 1 Headstock Assembly III Exploded View ...

Page 56: ...20 6 1 Headstock Assembly IV Exploded View Ⅰ Ⅱb Ⅱ Ⅲ Ⅳ Ⅴ ...

Page 59: ...23 7 1 Headstock Assembly V Exploded View Ⅶ Ⅶb Ⅵ ...

Page 62: ...26 9 1 Gear Box Assembly I Exploded View Ⅱ Ⅲ Ⅰ ...

Page 64: ...28 10 1 Gear Box Assembly II Exploded View ...

Page 67: ...31 11 1 Gear Box Assembly III Exploded View ...

Page 70: ...34 12 1 Brake Assembly Exploded View ...

Page 72: ...36 13 1 Saddle and Cross Slide Assembly Exploded View ...

Page 75: ...39 14 1 Tool Post and Compound Rest Assembly Exploded View ...

Page 77: ...41 15 1 Apron Assembly I Exploded View Ⅱ Ⅹ Ⅱ Ⅲ Ⅷ Ⅹ Ⅸ Ⅹ Ⅳ Ⅰ Ⅹ Ⅰ Ⅵ Ⅲ Ⅴ Ⅶ ...

Page 80: ...44 16 1 Apron Assembly II Exploded View Ⅺ Ⅹ Ⅲ Ⅻ Ⅸ Ⅹ Ⅶ ...

Page 83: ...47 17 1 Apron Assembly III Exploded View Ⅰ Ⅱ Ⅴ Ⅲ Ⅳ Ⅵ ...

Page 85: ...49 18 1 Apron Assembly IV Exploded View ...

Page 87: ...51 19 1 Tailstock Assembly I Exploded View ...

Page 89: ...53 20 1 Tailstock Assembly II Exploded View ...

Page 91: ...55 21 1 Steady Rest Assembly Small and Large Exploded View ...

Page 95: ...59 24 1 Travel Stop Assembly Exploded View ...

Page 100: ...64 27 2 Electrical Diagram ...