13

10.0

General description

Lathe bed

The lathe bed (A, Fig. 11) is made of high grade

cast iron. By combining high cheeks with strong

cross ribs, a bed with low vibration and high rigidity

is realized. Two precision ground v-slideways,

reinforced by heat hardening and grinding, are an

accurate guide for the carriage and headstock. The

main drive motor is mounted in the stand below

headstock.

Headstock

The headstock (B, Fig. 11) is cast from high grade,

low vibration cast iron. It is bolted to the bed by

four screws with two adjusting screws for

alignment. In the head, the spindle is mounted on

two precision taper roller bearings. The hollow

spindle has Morse Taper #5 with a 1-1/2" bore.

Carriage

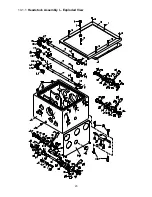

The carriage (A, Fig. 12) is made from high quality

cast iron. The sliding parts are smooth ground. The

cross slide is mounted on the carriage and moves

on a dovetailed slide which can be adjusted for

play by means of the gibs.

The compound slide (B, Fig. 12), which is mounted

on the cross slide (C, Fig. 12), can be rotated

through 360

°

. The top slide and the cross slide

travel in a dovetail slide and have adjustable gibs.

A four way tool post is fitted on the top slide.

Four way tool post

The four way toolpost (D, Fig. 12) is mounted on

the top slide and allows a maximum of four tools to

be mounted simultaneously. Remember to use a

minimum of two clamping screws when installing a

cutting tool.

Apron

The apron (E, Fig. 12) is mounted to the carriage.

In the apron a half nut is fitted. The half nut gibs

can be adjusted from the outside. The half nut is

engaged by use of a lever. Quick travel of the

apron is accomplished by means of a bed-

mounted rack and pinion, operated by a

handwheel on the front of the apron.

Tailstock

The tailstock (A, Fig. 13) slides on a v-way and can

be locked at any location by a clamping lever. The

tailstock has a heavy duty spindle with a Morse

Taper #3.

Leadscrew and feed Rod

The leadscrew (B, Fig. 13) and feed rod (C, Fig.

13) are mounted on the front of the machine bed.

They are connected to the gearbox at the left for

automatic feed and lead, and are supported by

bushings on both ends. Both are equipped with

brass shear pins.

Figure 11

Figure 12

Figure 13

Summary of Contents for GH-1440

Page 23: ...23 14 1 1 Headstock Assembly I Exploded View ...

Page 26: ...26 14 2 1 Headstock Assembly II Exploded View ...

Page 28: ...28 14 3 1 Headstock Assembly III Exploded View ...

Page 30: ...30 14 4 1 Gearbox Assembly I Exploded View ...

Page 33: ...33 14 5 1 Gearbox Assembly II Exploded View D C B ...

Page 36: ...36 14 6 1 Apron Assembly I Exploded View ...

Page 38: ...38 14 7 1 Apron Assembly II Exploded View A D E C B A B C D E ...

Page 40: ...40 14 8 1 Saddle and Cross Slide Assembly Exploded View ...

Page 43: ...43 14 9 1 Top Slide and Tool Post Exploded View ...

Page 45: ...45 14 10 1 Tailstock Assembly Exploded View ...

Page 47: ...47 14 11 1 Bed and Shaft Assembly Exploded View ...

Page 50: ...50 14 12 1 Stand and Brake Assembly Exploded View ...

Page 52: ...52 14 13 1 End Gear Assembly Exploded View ...

Page 56: ...56 14 16 1 Steady Rest Parts List ...

Page 61: ...61 14 20 1 Accessories I Exploded View ...

Page 65: ...65 15 0 Electrical Connections 15 1 Wiring Diagram 1 Phase ...

Page 66: ...66 15 2 Wiring Diagram 3 Phase ...

Page 68: ...68 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...