14

Adjustments

Before attempting any adjust-

ments, make sure the trigger is released and

remove the power cord from the power source

to avoid injury from unexpected starting or

electrical shock. Failure to comply may cause

serious injury!

Note:

Your miter saw was adjusted at the factory.

However, during shipment slight misalignment may

have occurred. Check the following settings and

adjust if necessary prior to using this miter saw.

Bevel Stop Adjustments

To avoid injury from

unexpected starting or electrical shock, make

sure the trigger is released and remove the

power cord from the power source.

90°(0°) Bevel Adjustment

1. Set the miter angle to 0° (see

Miter Angle

on

page 15).

Note:

A

bevel

angle of 0° corresponds to a

blade-

to-miter-table

angle of 90°.

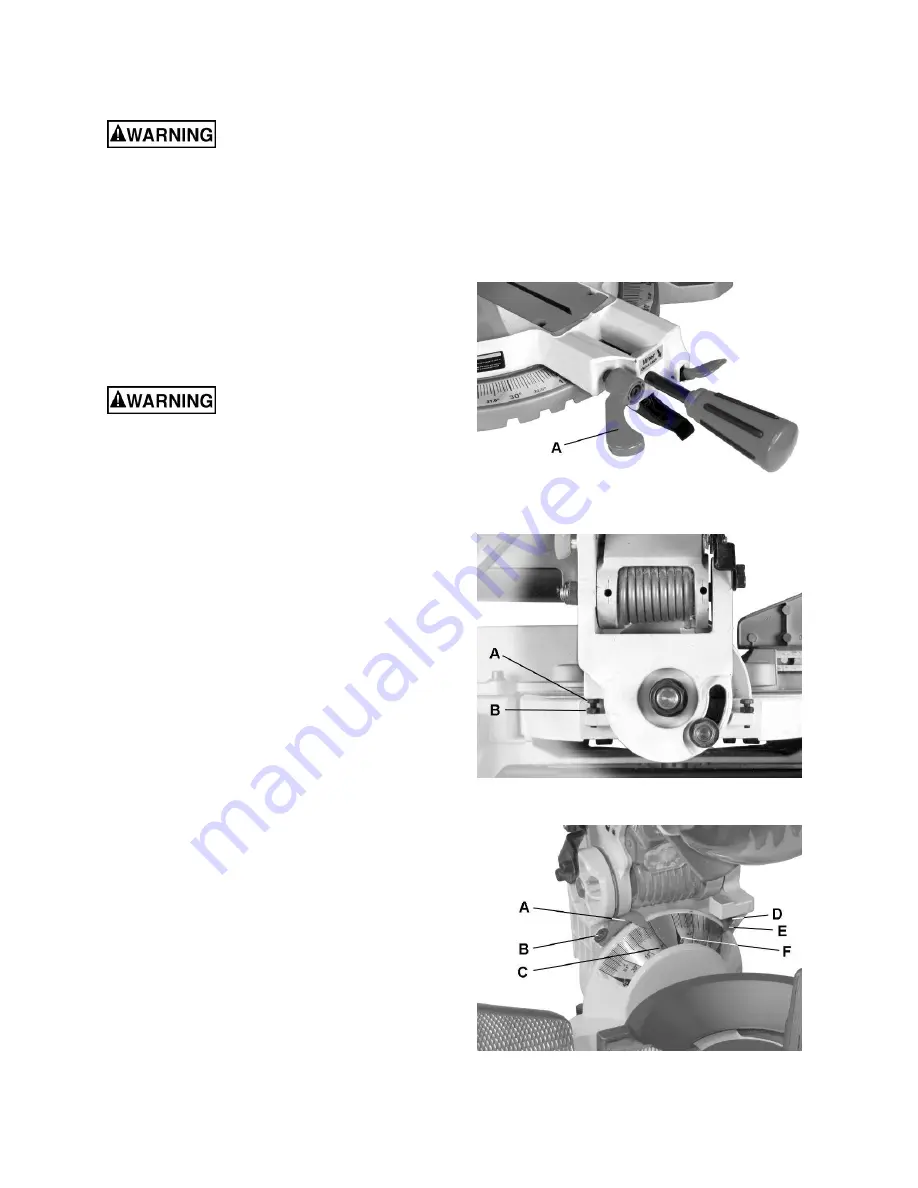

2. Turn

the

bevel lock handle

(A, Fig. 6) clockwise

to loosen and tilt the cutting arm to the 0° bevel

angle. Turn the

bevel lock handle

(A)

counterclockwise to tighten.

3. Place a combination square on the miter table

with the rule against the table and heel of the

square against the saw blade.

If the blade is not 90° to the miter table:

4. To adjust, tilt the cutting arm to 45°, loosen the

lock nut

(B, Fig. 7) and turn the

stop bolt

(A,) in

or out accordingly.

5. Tilt the cutting arm back to the right and

recheck alignment.

6. Repeat steps 1–4 if necessary until the blade is

90° to the table, then tighten the

lock nut

(B,

Fig. 7) to secure the

stop bolt

(A, Fig. 7).

Bevel Scale Indicators

1. Set the blade to be exactly 90°(0°) to the table.

2. With cross-point screwdriver, loosen two

bevel

indicator screws

(B, D, Fig. 8).

3. Adjust

bevel indicators

(A, E, Fig. 8) to the

“0”

marks

(C, F, Fig. 8)

on the bevel scale and

retighten the

screws

(B, D).

Figure 6

Figure 7

Figure 8

Summary of Contents for Bench JMS-10CMS

Page 9: ...9 Features...

Page 30: ...30 Assembly Drawing...

Page 31: ...31 Assembly Drawing continued...

Page 32: ...32 Assembly Drawing continued...

Page 33: ...33 Wiring Diagram...

Page 34: ...34 Notes...

Page 35: ...35 Notes...