13

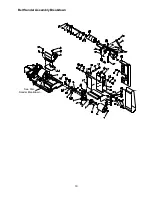

4. If the miter slot is not parallel, loosen the two

socket head cap screws (A, Fig. 13) and

adjust for parallel. Tighten the two screws

when the adjustment is complete.

5. Always maintain a gap of approximately 1/16”

between the table edge and disc. Once the

table is square and parallel to the disc adjust

the 90° stop. Loosen hex nut (B, Fig. 13) and

tighten the set screw (C, Fig. 13) until it

contacts the trunnion. Tighten hex nut.

6. If the pointer does not line up with the “0” on

the scale loosen the screw and adjust for “0”.

Tighten the screw.

7. The table can be tilted between 0°-45° by

loosening the handle (D, Fig. 13) and tilting the

table to the desired angle. Tighten the handle.

Always maintain a gap of approximately 1/16”

between the table edge and disc.

Note:

The belt table can be removed and the

disc table can be used in its place. There are

two holes in the base below the sanding belt

that will accommodate the disc table’s support

rod and locking handle.

Sanding Disc Replacement

1. Disconnect machine from the power source.

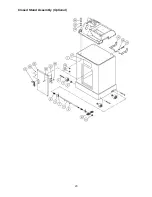

2. Loosen the handle (C, Fig. 14) and remove the

table assembly (A, Fig. 14).

3. Turn the knob (B, Fig. 14) and swing open the

cover.

4. Remove old sanding disc by stripping from

wheel. Make sure the disc plate is clean.

5. Press the new disc firmly into place.

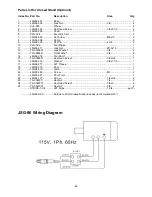

Center Point

The center point (A, Fig. 15) provided with the

sander can be used for sanding circles. The center

point can be locked in position by tightening the set

screws (B, Fig. 15).

On/Off Switch

The machine can be turned on by moving the

switch (C, Fig. 15) to the up position. The key (D,

Fig. 15) can be removed when the machine is in

the off position. With the key removed the switch

will not operate.

Figure 13

Figure 14

Figure 15