10

Adjustments

Sanding Belt Table Adjustment

Always disconnect the sander

from the power source before servicing or

making any adjustments. Failure to comply

may cause serious injury.

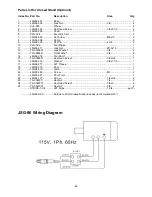

1. Place a square on the sanding belt table with

one edge along the graphite pad, or sanding

belt (Figure 4).

2. If the table is not square to the belt adjust the

table by loosening the two locking handles.

Adjust to the square position and tighten

handles.

3. Place a combination square (A, Fig. 5) in the

miter gauge slot (B, Fig. 5) and check the

distance from the slot to the edge of the

sanding belt. Slide the square along the slot to

the other end of the belt and check the

distance. The distances should be equal to

ensure that the miter gauge travels parallel to

the belt. Loosen the two socket head cap

screws at the bottom of the table, which hold

the table and left trunnion in place to adjust the

distance.

4. Always maintain a gap of approximately 1/16”

between the table edge and belt. Once the

table is square and parallel to the belt adjust

the 90° stop. Loosen the hex nut and tighten

the set screw until it contacts the guide pin,

(Figure 6). Tighten the hex nut. Repeat for the

other side.

5. If you need to sand at a precise angle, loosen

the handles that secure the table in place. Set

a combination square on the table and adjust

to the desired angle. Always maintain a gap of

approximately 1/16” between the table edge

and belt.

Note:

The belt table can be removed and the

disc table can be used in its place. There are

two holes in the base, below the sanding belt,

that will accommodate the disc table’s support

rod and locking handle.

Figure 4

Figure 5

Figure 6