Technical Specifications

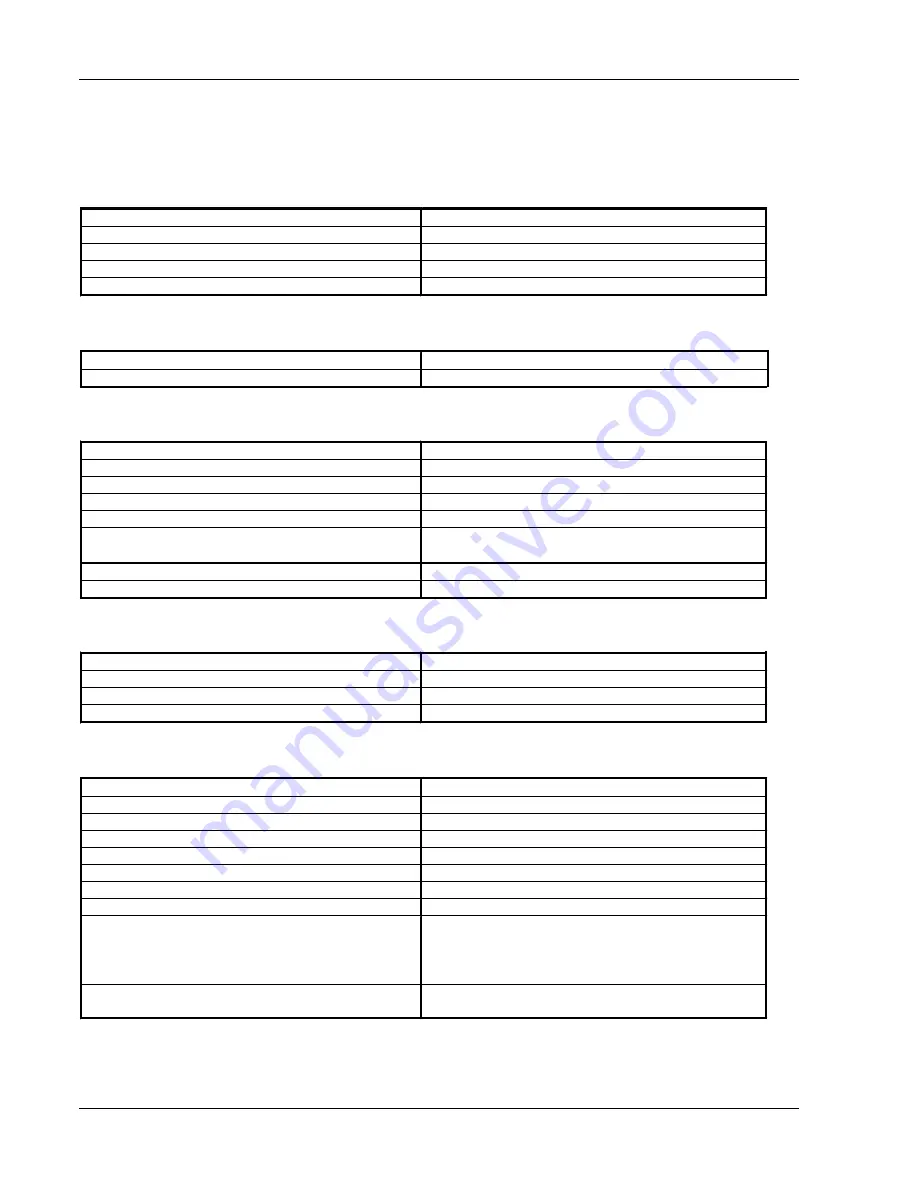

Operating Modes

Online positioning drive by fieldbus

CAN, RS485 or RS232

Positioning drive by PLC interface

digital PLC I/O

Positioning drive by pulse/direction

RS422, 24 V or 5 V signals

Speed controller by analog command

10 Bit analog input

Master/Slave positioning drive

RS422 or 24 V encoder signals

Controller Loop Data

Sampling time digital speed loop

0.25 ms (4 kHz)

Sampling time digital position loop

1.0 ms (1 kHz)

Power Stage Specifications

Max. RMS phase current

8.5 A

rms

Max. phase current

12 A

DC

Max. output voltage

U

DC-BUS

Max. output power

1.8 kW

Short-circuit protection of motor output

motor phases to DC-BUS and amongst

Min. inductance of motor winding

≥

0.5 mH (U

DC-BUS

≤

70V)

≥

1.0 mH (U

DC-BUS

≤

170V)

Length of motor cable

max. 10 m (otherwise consult supplier)

Frequency of output current ripple

16.4 kHz

Electrical Specifications

Control logic supply

18 ... 30 V

DC

, ripple < 10%

Fuse of control logic supply (recommended)

3 A T

Bus power supply (U

DC-BUS

)

24 ... 170 V

DC

Fuse of bus power supply (recommended)

10 A T

Operating Conditions

Operating temperature

0 ... 40°C

Storage temperature

-10. .. 70°C

Humidity (non-condensing)

5. .. 95% (RH-2 according to IEC 61131-2)

Pollution degree

2 (according to IEC 61131-2)

Protection class

IP20

Place of installation

dust-free, dry, lockable (e.g. electrical cabinet)

Mounting position

vertical (refer to “ECOSTEP Installation“)

Installation altitude

up to 1000 m above sea level (full ratings)

Power loss dissipation:

@ 5,7A

rms

(U

DC-BUS

≤

170V)

@ 7,5A

rms

(U

DC-BUS

≤

100V)

@ 8,5A

rms

(U

DC-BUS

≤

170V)

≤

40 W

≤

40 W

≤

70 W

Cooling

convection

heat sink required if cont. power loss dissipation >40W

Jenaer Antriebstechnik GmbH

ECOSTEP

200

S4 (13)

Safety Instructions / Technical Specifications / Installation, Date 09/2007