16

Inside surface of the posts is not well greased. Add grease.

Lowering too slow

The throttle valve jammed.

Clean or replace.

The hydraulic oil is dirty.

Change the oil.

The anti-surge valve jammed.

Clean it.

The oil hose jammed.

Replace it.

The steel cable is

abraded

No grease when installation or out of lifetime

Replace it.

6. Maintenance

Easy and low-cost routine maintenance can ensure the lift work normally and safely. Following are requirements for routine

maintenance. You may decide

the frequency of routine maintenance by consulting your lift’s working conditions and time.

THE FOLLOWING PARTS NEED TO BE LUBRICATED

S/N

Name

1

Slider

2

Wire wheel

3

Shaft

Summary of Contents for JA4000FP

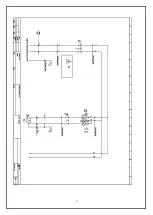

Page 18: ...18 7 Annex Annex1 Packing list of the whole lift Annex2 Overall diagram ...

Page 19: ...19 Annex3 Floor plan ...

Page 20: ...20 Annex 4 Steel cable connection ...

Page 21: ...21 ...

Page 22: ...22 ...

Page 24: ...24 ...

Page 25: ...25 ...