Chapter

2 Part C lnline six-cylinder engine

Oil pump mounting bolt

Short

1 0

Long

17

Rear main bearing cap bolts

8 0

Rocker arm bolts

1 9

Rocker arm cover-to-cylinder head bolts

With RTV

28 in-lbs

With permanent gasket

55

in-lbs

Tensioner bracket-to-block bolts

14

Timing chain cover-to-block

Bolts

5

Studs

1 6

Vibration damper center bolt (lubricated)

80

1 General information

This Part of Chapter

2

is devoted t o in-vehicle repair procedures for

the

six-cylinder engine. All information concerning engine removal

and installation and engine block and cylinder head overhaul can be

found in Part

D of this Chapter.

The following repair procedures are based on the assumption that

the engine is installed in the vehicle. If the engine has been removed

from the vehicle and mounted on a stand, many of the steps outlined

in this Part of Chapter 2 will not apply.

The Specifications included in this Part of Chapter 2 apply only t o

the procedures contained in this Part. Part

D of Chapter 2 contains the

Specifications necessary for cylinder head and engine block rebuilding.

2

Repair operations possible w i t h the engine in the vehicle

Many major repair operations can be accomplished without removing

the engine from the vehicle.

Clean the engine compartment and the exterior of the engine with

some type of pressure washer before any work is done. It will make

the job easier and help keep dirt out of the internal areas of the engine.

Remove the hood, if necessary, to improve access t o the engine as

repairs are performed (refer t o Chapter 11 if necessary).

If vacuum, exhaust, oil or coolant leaks develop, indicating a need

for gasket or seal replacement, the repairs can generally be made with

the engine in the vehicle. The intake and exhaust manifold gaskets,

timing cover gasket, oil pan gasket, crankshaft oil seals and cylinder

head gaskets are all accessible with the engine in place.

Exterior engine components, such as the intake and exhaust

manifolds, the oil pan (and the oil pump), the water pump, the starter

motor, the alternator, the distributor and the fuel system components

can be removed for repair with the engine in place.

Since the cylinder heads can be removed without pulling the engine,

valve component servicing can also be accomplished with the engine

in the vehicle. Replacement of the camshaft and timing chain and

sprockets is also possible with the engine in the vehicle.

In extreme cases caused by a lack of necessary equipment, repair

or replacement of piston rings, pistons, connecting rods and rod bear-

ings is possible with the engine in the vehicle. However, this practice

is not recommended because of the cleaning and preparation work that

must be done t o the components involved.

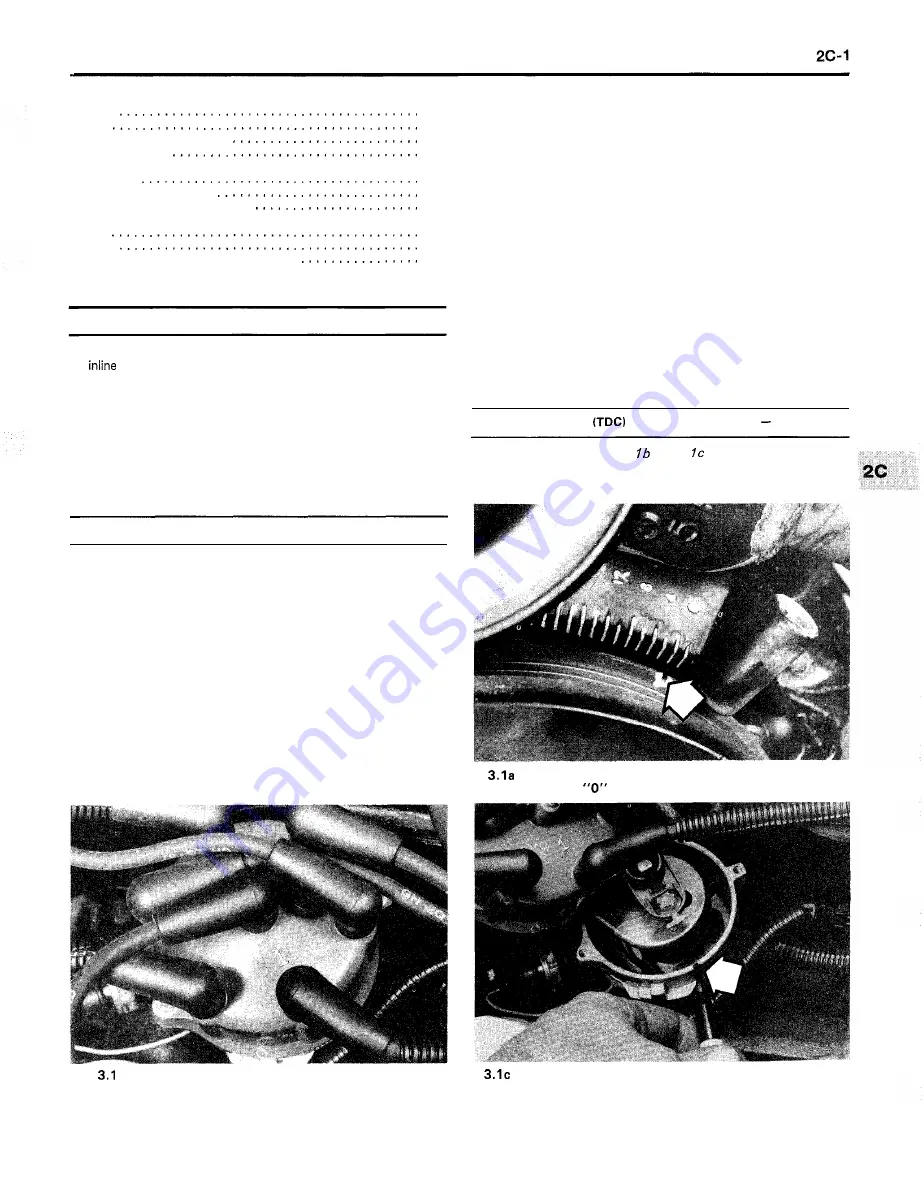

3 Top Dead Center

for number one piston

locating

Refer to illustrations

3.

la,

3.

and

3.

See Chapter 2, Part A, Section

3

for this procedure, but refer to the

illustrations and specifications included in this Section.

Align the notch (arrow) on the vibration damper w i t h

the

on the timing chain cover

b Locate the number one spark plug terminal on the

distributor cap, make a mark on the distributor housing,

directly under the number one plug terminal,

. . .

. . .

then remove the distributor cap and verify that the

rotor is pointing at the mark (arrow)

The Motor Manual Guy

Summary of Contents for cherokee 1989

Page 2: ...The Motor Manual Guy...

Page 3: ...The Motor Manual Guy...

Page 32: ...The Motor Manual Guy...

Page 191: ...The Motor Manual Guy...

Page 266: ...The Motor Manual Guy...

Page 267: ...The Motor Manual Guy...