21

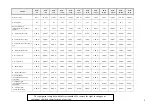

2 – REDUCTION GEAR

The oil change of all gearboxes should be carried out

at least once a year

, depending on the

frequency of use of the equipment:

Rep

Item

Pos.nr

Type

Type

Typen

Boîtes d’engrenages / gear box / getriebekasten

Qté Qty

Menge

Litres Liter

Liter

Huile

Oil

Ol

Marques

Makes

N°

Monté sur

Fitted on

Auf gehoben

1

EVR 8-6

814 181

EPAN 5

EPAN 5

EPAN 5

3 x 2 l.

SAE 90

GB

11 l.

BERMA

2

EVR 10-6 to

15-12

814 173

Ou

814 181

EPAN 5

EPAN 5

EPAN 5

EPAN 5

EPAN 5

EPAN 5

3 x 2 l.

SAE 90

GB

15,5 l.

BERMA

3

EVR 14-11 to

21-15

814 174

ou 814 182

EPAN 5

EPAN 5

EPAN 5

EPAN 5

EPAN 5

EPAN 5

3 x 2 l.

SAE 90

GB

4

EVR 14-11 to

21-15

814 186

2 plateaux EPAN 6

2 plates EPAN 6

2 tafellander epan 6

20 l.

SAE 90

BERMA

5

EVR 14-11 to

21-15

814 190

Vis horizontales

EPAN 6

EPAN 6

horizontal beaters

Horizontale

schrauben

2 x 2 l.

SAE 90

GB

6

EVR 8-6 to

10-6

814 160

Fond mouvant

Moving floor

Rollboden

2 l.

SAE 90

ROCHLING

7

EVR 12-8 to

15-12

814 136

Fond mouvant

Moving floor

Rollboden

2.4 l

SAE 90

ROCHLING

8

EVR 14-11 to

16-12

814 130

Fond mouvant

Moving floor

Rollboden

2 l.

SAE 90

ROCHLING

9

EVR 18-14 and

21-15

814 161

Fond mouvant

Moving floor

Rollboden

3,5 l.

SAE 90

ROCHLING

10

EVR 8-6 to

21-15

814 177

pompe

Pump

Pumpe

2,22 l.

SAE 90

BIMA

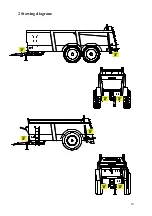

3 - CHAINS

Marine or vaucanson transmission chains (moving floor).

1.

Follow instructions on the stickers placed at the front of the spreader for moving floor

chains (see page 13).

2.

The

tension

of the chains should be

moderate

. CONTROL THE CHAIN ALIGNMENT.

3.

During the running in period, the chains may stretch significantly,

tighten again if

necessary

.

4.

When the tensioners are at their maximum for adjusting chain,

cut two links

and tighten

again.

5.

Check the

tightness of attachment screws

on the moving floor connector bars, especially

during the first hours of operation.

6.

Check the

state of the drive sprockets

for the moving floor chains. As soon as they are

damaged change them to avoid any risk of derailment.