01 - Machine

33 - Cleaning

00 - General

01 - 27

9813/7750-1

01 - 27

00 - General

....................................................

....................................................

Introduction

WARNING

When using cleaning agents, solvents

or other chemicals, you must adhere to

the manufacturer's instructions and safety

precautions.

CAUTION

To avoid burning, wear personal

protective equipment when handling hot

components. To protect your eyes, wear goggles

when using a brush to clean components.

Notice:

Cleaning metal parts with incorrect

solvents can cause corrosion. Use only

recommended cleaning agents and solvents.

Notice:

The efficiency of the rams will be affected

if they are not kept free of solidified dirt. Clean dirt

from around the rams regularly. When leaving or

parking the machine, close all rams if possible to

reduce the risk of weather corrosion.

Notice:

Never use water or steam to clean inside

the operator station. The use of water or steam

could damage the machine electrics and render

the machine inoperable. Remove dirt using a

brush or damp cloth.

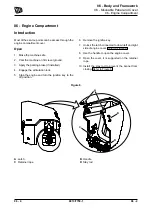

Clean the product with water and/or steam. Do not

let mud, debris etc. to collect on the product.

Before you do any service procedures that require

components to be removed:

•

The cleaning must be done either in the area

of components to be removed, or in the case

of major work, or work on the fuel system, the

whole engine and the surrounding product must

be cleaned.

•

When cleaning is complete, move the product

away from the wash area or alternatively,

remove the material washed from the product.

When you remove components, be aware of

exposure to dirt and debris. Cover any open ports

and remove the deposits before proceeding.

Detergents

Do not use a full strength detergent. Always

dilute the detergents as per the manufacturer's

recommendations, or damage to the paint finish can

occur.

Always obey the local regulations regarding the

disposal of debris created from cleaning the product.

Pressure Washing and Steam Cleaning

CAUTION

When using a steam cleaner, wear

safety glasses or a face shield as well as

protective clothing. Steam can cause personal

injury.

Summary of Contents for CT160

Page 2: ...9813 7750 1 Notes Find manuals at https best manuals com...

Page 4: ...Notes 9813 7750 1 Find manuals at https best manuals com...

Page 8: ...Notes 01 2 9813 7750 1 01 2 Find manuals at https best manuals com...

Page 22: ...Notes 01 16 9813 7750 1 01 16...

Page 26: ...Notes 01 20 9813 7750 1 01 20...

Page 32: ...Notes 01 26 9813 7750 1 01 26...

Page 36: ...9813 7750 1 2018 05 25 Acronyms Glossary PIN Product Identification Number...

Page 38: ...Notes 06 2 9813 7750 1 06 2...

Page 41: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com...