JAY

•

LOR

®

Operator’s Manual

- 32 -

Trailer Units - Models 2875 - 21000

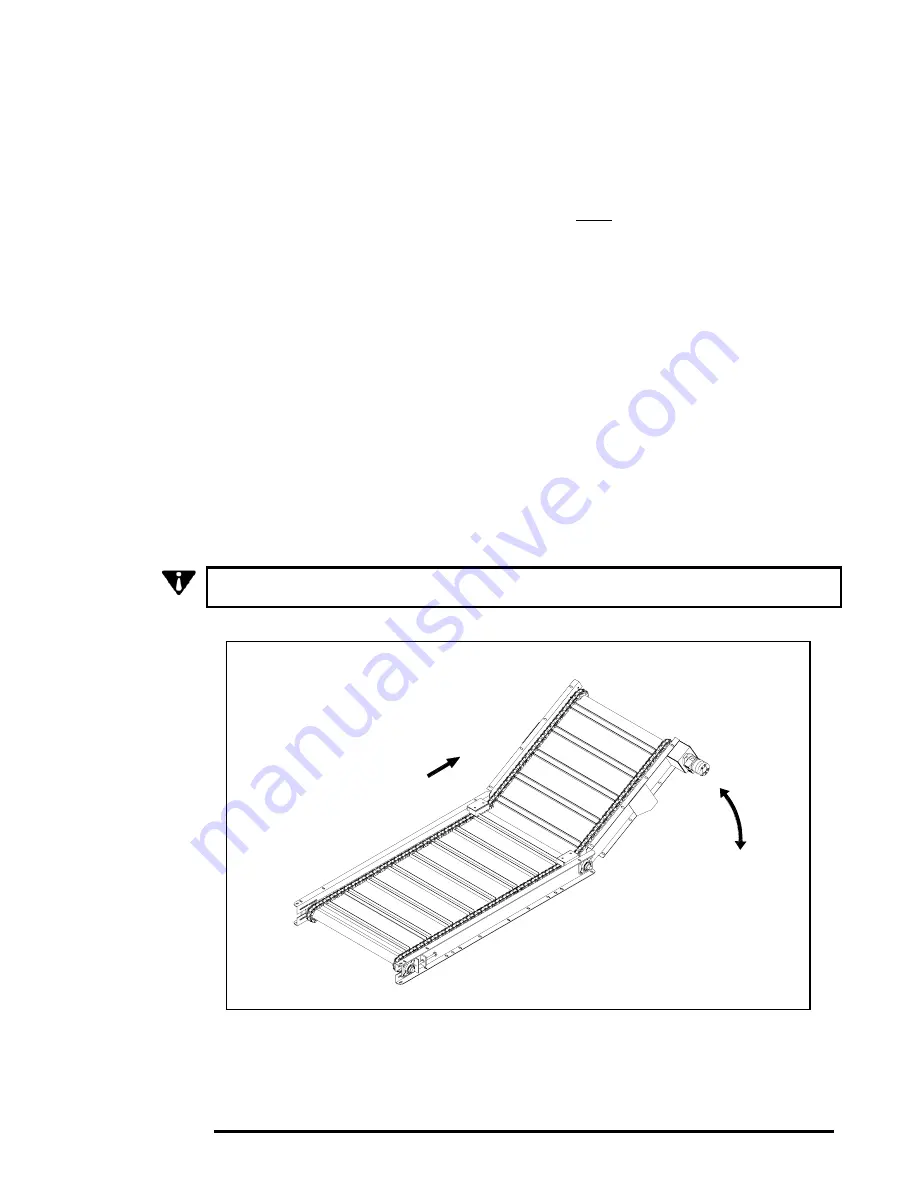

Right/Left Discharge – 6’ Flat w/ Height Adjustable Wing Conveyor

Machines that are equipped with right or left discharge have a section of the conveyor that

can be raised and lowered. Depending on the options on your JAY

•

LOR

®

, raising and

lowering the conveyor can be done hydraulically or manually.

For models equipped with a manual lift, the conveyor

must

be stopped in order to raise and

lower it. A turnbuckle assembly is used to adjust the wing conveyor height. Simply turn the

body on the turnbuckle clockwise or counterclockwise, depending on whether the wing is to

be raised or lowered.

For models equipped with hydraulic lift discharge, there are two available options for the

conveyor operation. One system employs the Lock Collar System. Machines equipped with

this system have cylinder lock collars supplied with the equipment. The collars are each

different sizes, and are stacked on the lift cylinder’s stroke. The number of lock collars used

determines the lowering height of the wing. Once the desired height is set, the conveyor is

lowered (cylinder retracts) until it bottoms on the lock collar(s). The hydraulic plumbing is

designed such that at this point the hydraulic motor on the conveyor will engage. Once the

control lever is reversed, the hydraulic motor will disengage and the conveyor wing will raise

(cylinder extends).

In the Diverter Valve System, the conveyor must be stopped before a selector valve is

activated. To activate the selector valve, simply pull the attached rope. When the rope is

pulled, the hydraulics are used to raise and lower the conveyor. When the conveyor reaches

the desired position, release the rope, and the conveyor will begin to unload.

Important: Always ensure that there are no obstacles beneath the conveyor that could

cause damage or be damaged when the conveyor is lowered.

Figure 17 - Right/Left Discharge Conveyor Assembly.

DI

SC

HA

RG

E

DI

RE

CTI

ON

RAISE/LOWER

WING EXTENSION