Page 17

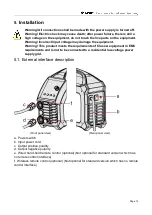

5.4. LIFT TIG welding torch and earth cable connection

1) Ensure that the power switch is turned off.

2) Insert the cable plug with the earth clamp into the positive socket on the front panel of the

welder and tighten it clockwise.

3) Insert the cable plug of the welding torch into the corresponding negative socket on the

front panel of the welder and tighten it clockwise.

Note! The positive and negative polarities should not be reversed as this will prevent

normal welding operation.

4) Connect the shield gas pipe input end of the welding torch to the output gas connection of

the gas pressure regulator and secure it firmly with a clamp.

(Wiring diagram)

NOTE! If you want to use long secondary cables (TIG torch and earth cable), you must

ensure that the cross-sectional area of the cable is increased appropriately in order to

reduce the voltage drop due to the cable length.