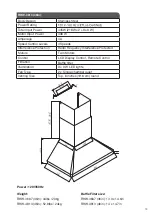

5. Align Exhaust Duct Base Gasket (Part D) with the

exhaust opening on top of the Range Hood, place

Exhaust Duct Base (Part C) on top of it, and fasten

using Exhaust Duct Base Screws (Part K).

NOTE:

Additional step for 48in models:

Fix two Duct Cover Hooks with screws provided

(Part O) to the top of the hood towards the wall

side.

You will use these two Hooks to fasten the

Exhaust Duct Cover Top for additional stability.

6. Calculate the height of the duct and extend

approximately 6” (15 cm) longer than required. Con-

nect the duct to the Exhaust Duct Base on the Hood

Body and seal the connection with HVAC foil tape or

duct tape to make sure joints are secure and

air-tight.

7. Raise the Hood Body and hang it onto the screws

on the wall. Tighten screws to secure hood to the

wall.

8.

CAUTION

- Make certain the range hood is

secure before releasing!

9. For safety purposes, pre-drilled mounting holes

are provided through the back of the hood. For a

more secure installation, use as many mounting

holes as needed to secure the unit from the inside of

hood.

10. Connect the upper end of the duct to the vent

system in the wall or ceiling.

11. Carefully slide the top half of the Exhaust Duct

Cover into the Lower Exhaust Duct Cover (Parts B).

12. Fasten the Lower Exhaust Duct Cover to the

Hood Body using Exhaust Duct Cover Screws (part

J).

13. Carefully extend the Upper Exhaust Duct Cover

until it reaches the Duct Cover Mounting Bracket.

14. Fix the Upper Exhaust Duct Cover to the Duct

Cover Mounting Bracket using Exhaust Duct Cover

Screws (Part J) on each side, left and right sides of

the Exhaust Duct Cover.

11