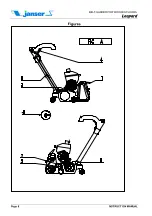

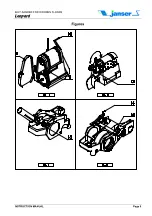

BELT-SANDER FOR WOODEN FLOORS

Leopard

Page 16

INSTRUCTION MANUAL

EC COMPLIANCE DECLARATION

73/23CEE, 89/392/CEE, 91/368/CEE / 89/336/CEE, 92/31/CEE, 93/44/CEE / 93/68/CEE

We

Janser GmbH

Böblinger Straße 91

71139 Ehningen

GERMANY

declare under our responsibility that the product

Belt Sander

Leopard

to which this declaration relates complies with the following standards or other normative document(s):

à

Safety of machinery - Basic concepts, general principles for design

Basic terminology, methodology EN 292 Part 1 –September 1991

à

Safety of machinery - Basic concepts, general principles for design

Technical principles and specification EN 292 Part 2 September 1991

à

Safety of machinery - Electrical equipment of machines

Part 1 : General requirements EN 60204-1 - October 1992

à

Safety of household and electrical appliances - General requirements

EN 60335-1 - June 1988 + Modification 2, 5, 6, A51, A52, A53, A54, A55

à

Limits and methods of measurements of radio disturbance characteristics of electrical motor-

operated and thermal appliances for households and similar purposes, electric tools and similar

electric apparatus - EN 55014 - Edit. 1987 + modification A2 (1990)

à

General emission standard - Residential, commercial and light industry EN 50082-1 Edit. 1992

following the provisions of the Directives:

73/23CEE, 89/392/CEE, 89/336/CEE, 91/368/CEE 92/31/CEE, 93/44/CEE 93/68/CEE

Management

W.Müller

Technical Responsible

H.Serediuk