BELT-SANDER FOR WOODEN FLOORS

Leopard

INSTRUCTION MANUAL

Page 11

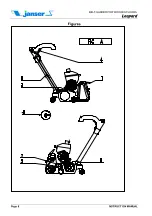

SETTING THE MACHINE UP

In order to start up the machine, proceed as follows:

1.

Familiarize yourself with the machine and read all the danger, warning and caution instructions. Make

sure that all operators have read this manual.

2.

Place the dust bag on the elbow and tie the cord above the flange on the elbow.

3.

Find the power socket. The socket must be compatible with the plug. To avoid danger, the socket must

be earthed and protected with a fuse (20 amp).

4.

Wind the cable around the pig's tail support. Keep the cable out of the machine's way.

5.

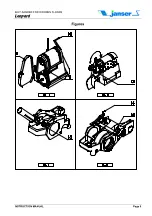

Open side guard 9 (fig. B).

6.

Lower the tensioning roller by turning lever 10 (fig. B) clockwise.

7.

Insert the abrasive belt and allow it to protrude from the side by about 2 centimetres.

WARNING:

Only use 750x203 mm abrasive belts.

8.

Stretch the belt by turning lever 10 (fig. B) anticlockwise.

9.

Put the plug into the socket.

10. Make sure that lever 4 (fig. A) is hooked up and the roller is off the floor.

11. Turn switch lever 8 (fig. A) momentarily from position 0 to the START position, and bring it back to 0

12. Observe the behaviour of the abrasive belt. Follow the "PROCEDURES FOR CENTRING THE

ABRASIVE BELT".

13. Close side guard 9 (fig. B).