BELT-SANDER FOR WOODEN FLOORS

Leopard

Page 12

INSTRUCTION MANUAL

MACHINE OPERATION

DANGER:

Sanding wooden floors may lead to an explosive environment. Cigarettes, cigars,

pipes, lighters, pilot lights and all other sources of fire may cause an explosion if

they are used while sanding. Sources of fire must be completely removed from

the work area.

DANGER:

Poorly ventilated work areas may lead to an explosive environment when certain

combustible materials are present in the air, such as, for example, solvents,

thinners, alcohols, fuels, some paints, sawdust and other combustible materials.

Machines for sanding floors can cause combustible materials and vapours to

ignite. Read the manufacturers' instructions on each chemical product used in

order to decide whether it is combustible. Keep the work area well ventilated.

DANGER:

Dust created by sanding may spontaneously ignite and cause injury or damage.

Dust from sanding must be dealt with suitably. Always empty the sanding dust into

metal containers located outside the building.

DANGER:

Dust created by sanding may spontaneously ignite and cause injury or damage.

Empty the dust bag when it is one-third full. Empty the dust bag each time after

finishing with the machine. Never leave the dust bag unattended when it contains

sanding dust.

DANGER:

Knocking against nails while sanding may cause explosion or start a fire. Always

sink all nails completely before sanding the surfaces.

1.

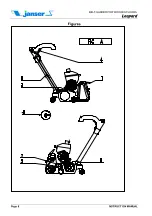

Make sure that lever 4 (fig. A) is hooked up and the roller is off the floor.

2.

Turn switch lever 8 (fig. A) from position 0 to the START position, hold it their until the motor has

reached sufficient rotary speed, then release the switch lever, which automatically returns to work

position 1.

WARNING:

During the winter, with very low temperatures, if the first startup is difficult, remove

the abrasive belt, start up the motor and allow it to idle for a few minutes. Then

replace the belt and repeat the startup operations described above.

WARNING:

This machine is fitted with a safety switch. If there is a power failure during the

work, the contactor automatically trips and prevents the machine from starting up

accidentally when power is restored. In order to start work again, the startup

procedure described above must be repeated.