2

MS5027PR

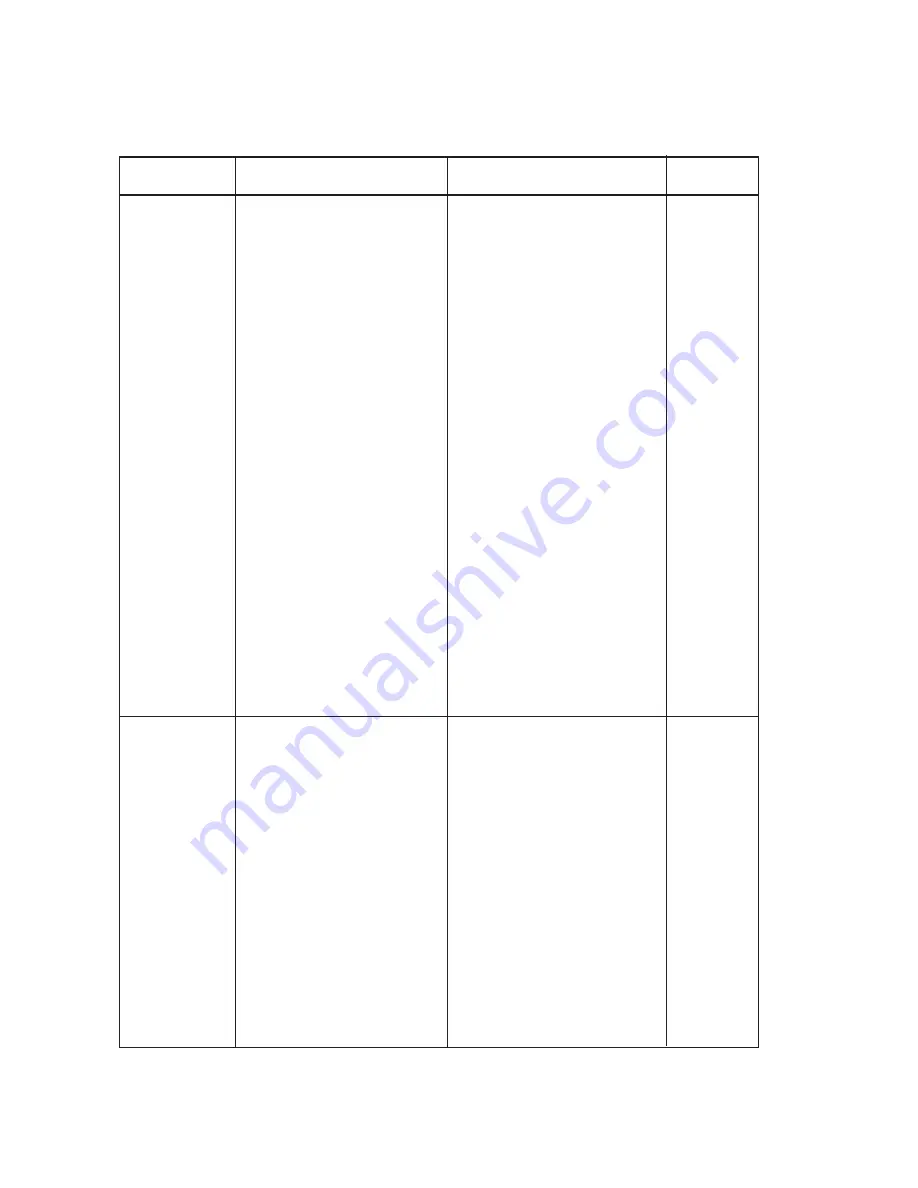

WHAT TO DO WHEN

CONDITION

CAUSE

HOW TO FIX

REFERENCE

1. SKIPPING

1. NEEDLE IS NOT INSERTED

INSERT THE NEEDLE PROPERLY.

STITCHES

PROPERLY.

2. NEEDLE IS BENT OR WORN.

CHANGE THE NEEDLE.

3. INCORRECTLY THREADED

RETHREAD.

4. NEEDLE OR THREAD ARE

USE THE RECOMMENDED

INAPPROPRIATE FOR

SEWING NEEDLE AND THREAD.

FABRIC BEING SEWN.

5. SEWING ON STRETCH

USE A #11 BLUE TIP NEEDLE.

FABRIC

6. PRESSER FOOT PRESSURE

ADJUST THE PRESSER BAR

IS TOO WEAK.

LEVEL TO MAKE THE

PRESSURE STRONGER.

7. INAPPROPRIATE NEEDLE

SEE MECHANICAL

P.22

BAR HEIGHT

ADJUSTMENT

“NEEDLE BAR HEIGHT”.

8. INAPPROPRIATE NEEDLE

SEE MECHANICAL

P.23

TO HOOK TIMING

ADJUSTMENT

“NEEDLE TO HOOK TIMING”.

9. INAPPROPRIATE NEEDLE

SEE MECHANICAL

P.24

TO HOOK CLEARANCE

ADJUSTMENT “NEEDLE

CLEARANCE TO HOOK.”

2. FABRIC NOT

1. PRESSER FOOT PRESSURE

ADJUST THE PRESSER BAR

MOVING

IS TOO WEAK.

LEVEL TO MAKE THE

PRESSURE STRONGER.

2. INCORRECT F.D. HEIGHT

SEE MECHANICAL

P.21

ADJUSTMENT “FEED DOG

HEIGHT.”

3. F.D. IS IN DOWN POSITION.

RAISE THE F.D. LEVEL.

4. THREAD ON BOTTOM SIDE

MAKE SURE TO BRING

OF FABRIC IS JAMMED UP.

BOTH NEEDLE AND BOBBIN

THREAD UNDER THE FOOT

WHEN STARTING SEWING.

5. FEED DOG TEETH ARE

CHANGE THE FEED DOG.

WORN.