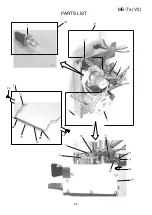

PARTS LIST

MB-7e (V2)

95

KEY

NO.

PARTS

NO.

DESCRIPTION

771032002

770252007

770515001

771017001

000001609

771018002

770243005

770244006

771506002

771507003

000101105

771501007

770245007

770249001

771019003

000002105

771020007

770242004

751074004

771509016

000166005

000066705

000193104

771611001

771603022

000061205

771043006

771041004

000101404

771042005

771502008

770414009

000078319

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Thread tension panel

Guide pin

Pretension (unit)

Thread tension bracket

Snap ring E-5

Release shaft

Thread release arm A

Thread release arm B

Thread tension A (unit)

Thread tension B (unit)

Setscrew 3x4

Micro switch (unit)

Thread tension release lever

Stopper spring

Sensor roller shaft

Snap ring E-3

Sensor slit

Sensor roller

Spacer

Printed circuit board G (unit)

Setscrew 4x8

Setscrew 3x8

TP setscrew 3x4

Thread tension panel (unit)

Thread tension (unit)

Nut 4-3-7

Spring

Roller shaft supporter

Setscrew 4x6

Shaft supporter mounting plate

Harness (unit) (6P)

Cord guide plate

Setscrew 3x6

Summary of Contents for MB-7e

Page 1: ...SERVICE MANUAL PARTS LIST MODEL MB 7e V2 First Edition 02 October 2020 ...

Page 2: ......

Page 72: ...PARTS LIST MB 7e V2 70 1 3 13 7 5 4 13 14 2 6 9 12 11 10 8 15 ...

Page 74: ...PARTS LIST MB 7e V2 72 ...

Page 76: ...PARTS LIST MB 7e V2 74 9 11 10 12 13 14 14 15 ...

Page 80: ...PARTS LIST MB 7e V2 78 1 3 4 6 9 11 13 2 5 7 8 10 12 14 16 18 15 17 19 ...

Page 82: ...PARTS LIST MB 7e V2 80 1 3 4 6 9 9 9 11 13 2 5 7 8 10 12 ...

Page 84: ...PARTS LIST MB 7e V2 82 3 1 2 4 5 6 7 8 9 10 11 12 13 15 16 17 14 18 19 20 21 22 23 24 25 ...

Page 86: ...PARTS LIST MB 7e V2 84 1 3 4 6 9 2 5 7 8 10 11 ...

Page 88: ...PARTS LIST MB 7e V2 86 1 1 3 4 6 9 11 13 2 5 7 8 10 12 14 14 16 18 15 17 12 16 ...

Page 94: ...PARTS LIST MB 7e V2 92 22 23 23 24 24 5 ...

Page 98: ...PARTS LIST MB 7e V2 96 10 9 ...

Page 100: ...PARTS LIST MB 7e V2 98 ...

Page 102: ...PARTS LIST MB 7e V2 100 17 28 29 ...

Page 104: ...PARTS LIST MB 7e V2 102 3 576 67 0 8 9 10 14 13 12 11 15 16 ...

Page 106: ...PARTS LIST MB 7e V2 104 1 2 9 5 5 6 7 12 5 11 3 13 8 13 13 13 5 5 5 4 10 8 14 11 ...

Page 108: ...PARTS LIST MB 7e V2 106 ...

Page 110: ...PARTS LIST MB 7e V2 108 ...

Page 112: ...PARTS LIST MB 7e V2 110 23 1 22 24 17 18 11 13 14 2 3 12 3 5 4 6 7 16 15 8 9 10 19 20 21 25 ...