2

Viewing a long combination ......................................... 69

Deleting and Inserting a Pattern ................................... 70

Duplicating a Pattern .................................................... 70

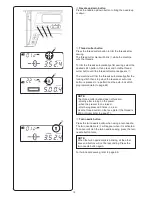

Uniform Stitch Adjustment ............................................ 71

nified Needle Drop osition

....................................... 71

Individual Stitch Adjustment ......................................... 72

CARE OF YOUR MACHINE

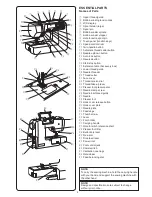

Cleaning the Hook Race and Feed Dog ...................... 73

Installing the Bobbin Holder ......................................... 73

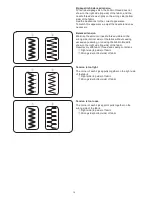

Correcting Deformed Stitch Patterns ............................74

Problems and Warning Signals .................................... 75

Troubleshooting ............................................................ 76

Stitch Chart .............................................................. 77-78

EC DECLARATION OF CONFORMITY ....................... 79

Summary of Contents for 4300QDC

Page 1: ...Instruction Book 4300QDC...

Page 79: ...77 Stitch Chart...

Page 80: ...78 Stitch Chart...

Page 82: ...80 Version 1 00 12 6 2018...

Page 83: ......

Page 84: ...809 850 956 EN...