Technical Specifications

Item no. 10201039, Revision 04

16 ( 36 )

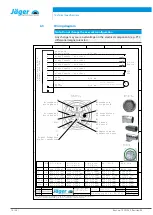

6.3

Wiring diagram

Note: Do not change the ex-works configuration.

Any change may cause overvoltage on the electrical components (e.g. PTC,

differential magneto resistor).

g

f

e

d

c

b

a

4

5

6

1

3

2

a

b

c

d

e

f

g

Bl.

von 1

Ü b e r s e t z u n g e n , Ve r v i e l f ä l t i g u n g e n u n d d i e W e i t e r g a b e a n D r i t t e , a u c h n u r a u s z u g s w e i s e ,

i s t o h n e s c h r i f t l i c h e G e h n e h m i g u n g d e r F a . A l f r e d J ä g e r G m b H u n t e r s a g t

Datum

Gepr.

Bearb.

Norm

System Technologie

Blatt 1

1.0

Projekt Nr.:

Version Nr.:

Zeichn.Nr.:

18.07.2008

Pinbelegung FS9 M (FP, PTC)

29025570

Alfred Jäger GmbH

Siemensstraße 8

61239 Ober Mörlen

G

E

S

p

i

n

d

e

l

s

t

e

c

k

e

r

F

S

9

M

S

p

i

n

d

l

e

p

l

u

g

F

S

9

M

C

B

A

D

H

F

L

siehe Tabelle / see chart

grün-gelb

green-yellow

siehe Tabelle / see chart

siehe Tabelle / see chart

siehe Tabelle / see chart

siehe Tabelle / see chart

gelb

yellow

grün

green

W

V

Stator

Stator

U

DFP

Digitale Feldplatte

Differential magneto resistor

0,75 mm²

0,14 mm²

0,14 mm²

U

V

W

PIN

3/7-4 pole

4/7-2 pole

2/7-2 pole

2/4-2 pole

3/7-2 pole

AC 7.01-2

PTC+

PTC-

AC 8.01-4

C

B

A

G

blau 0,14mm²

blue 0.14mm²

blau 0,14mm²

blue 0.14mm²

blau 0,14mm²

blue 0.14mm²

rot 0,14mm²

red 0.14mm²

rot 0,14mm²

red 0.14mm²

rot 0,14mm²

red 0.14mm²

blau 0,25mm²

blue 0.25mm²

blau 0,25mm²

blue 0.25mm²

blau 0,25mm²

blue 0.25mm²

weiß 0,20mm²

white 0.20mm²

weiß 0,22mm²

white 0.22mm²

weiß 0,25mm²

white 0.25mm²

braun 0,22mm²

brown 0.22mm²

grün 0,20mm²

green 0.20mm²

lila 0,22mm²

purple 0.22mm²

schwarz 0,5mm²

black 0.5mm²

blau 0,5mm²

blue 0.5mm²

braun 0,5mm²

brown 0.5mm²

blau 0,25mm²

blue 0.25mm²

blau 0,25mm²

blue 0.25mm²

blau 1mm²

blue 1mm²

braun 1mm²

brown 1mm²

schwarz 1mm²

black 1mm²

rot 0,25mm²

red 0,25mm²

rot 0,20mm²

red 0,20mm²

E

Kundenseite

Customer side

Rückseite

Back side

A

B

C

E

G

H

F

L

D

G

PTC+

L

---

---

F

Signal Feldplatte

Signal transmitter

C

Motorphase W

Motor phase W

B

Motorphase V

Motor phase V

A

Motorphase U

Motor phase U

D

PE Schutzleiter

PE conductor

E

PTC Masse

PTC earth

H

Feldplatte Masse

Transmitter earth

Kundenseite

Customer side

PTC

PTC