ENGLISH

19

Jacuzzi Whirlpool Bath DE99000A 3/06

Electronic Control Panel Operation

(with optional Chromotherapy/Illumatherapy

TM

lighting)

All tubs in this product line come with electronic controls and standard Chromotherapy or Illumatherapy

TM

. Read and follow

the operation instructions for the control system of your unit.

General Functions

This Jacuzzi tub is equipped with a seven button electronic control panel. The seven button panel controls a two speed pump/

motor, Chromotherapy or Illumatherapy

TM

lighting, air controls, and wave control. LED lights (in the control panel) indicate function

levels. When switching between functions, the LED for the inactive functions will dim and the active function will brighten.

The bath is equipped with a water level sensor(s). When the water level is

below

the sensor, the pump/motor can

not

be

activated. If the ON/OFF pump/motor button is pressed at this time, the pump/motor will not operate. When the water goes

above the water level sensor, the pump/motor can be activated. If the water level drops below the level sensor, the pump/motor

will shut

OFF

. To restart the pump/motor after the water level goes above the level sensor, the ON/OFF pump/motor button must

be pressed. The pump/motor will automatically shut off 30 minutes after the pump/motor was turned on.

NOTE:

Ensure the water level sensor located inside the bath is free of any soap or dirt buildup.

OPERATING INSTRUCTIONS (cont'd)

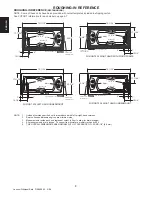

Bath Light

Right Air Valve

Left Air Valve

Left Air Valve

Status LED

Right Air Valve

Status LED

Pump/Motor

Status LED

ON/OFF

Pump/Motor

Wave Function

Toggle Switches

Normal Operation

(with the bath filled to the proper level)

Pump/Motor Switch

(ON/OFF )

Pressing the

button will turn ON the two speed pump/

motor at HIGH speed. Pressing a second time will turn OFF

the pump/motor. To change speeds use the Toggle buttons.

Pump/Motor Status LED

When the pump/motor is ON at HIGH speed all four LED

indicator lights will be lit. When the pump/motor is ON at

LOW speed the bottom LED indicator light will be lit.

Left Air Valve Switch

Pressing this

button will acitvate the left air valves use

the Toggle buttons to increase/decrease air flow to the left set

of jets. The air flow can be adjusted from no air to maximum

air.

Left Air Valve Status LED

The Left Air Valve Status LED will show four LED lights at

maximum air and only one LED light when the air is turned

OFF. Each additional LED indicates more air flow.

Right Air Valve Switch

Pressing this

button will acitvate the right air valves. Use

the Toggle buttons to increase/decrease air flow to the right

set of jets. The air flow can be adjusted from no air to maxi-

mum air.

Right Air Valve Status LED

The Right Air Valve Status LED will show four LED lights at

maximum air and only one LED light when the air is turned

OFF. Each additional LED indicates more air flow.

Bath Light Switch

(ON/OFF )

Pressing this

button will turn ON the white bath light(s).

Pressing the Toggle buttons at this time will increase or de-

crease light intensity. Pressing the button a second time will

access the saved favorite color. To cycle lighting colors use

the Toggle button. Pressing the Toggle button again will stop

the light cycling. The color displayed when the cycle has been

stopped will be saved as your favorite color. Pressing the

button a third time to turn OFF the light.

NOTE: When switching between functions, the LED for

the inactive functions will dim and the active function will

brighten.

Wave Function Switch

(ON/OFF )

Pressing this

button activates wave action by opening

and closing both right and left air valves. Pressing a second

time will turn OFF the wave action.

Toggle Buttons

The Toggle buttons, up

and down

, act on each of the

other buttons to increase, decrease, or modify functionality.

Use the up arrow to increase and the down arrow to decrease.

• Pressing a toggle button after pressing the Pump/Motor

button will increase or decrease speeds on the Pump/Mo-

tor. If the pump/motor is on HIGH speed press the down

arrow to select LOW speed. If the pump/motor is on LOW

speed press the up arrow to select HIGH speed.

• Pressing an up or down toggle button after pressing the

Bath Light button once will increase or decrease the white

light brightness. Pressing an up or down toggle button

after pressing the Bath Light button twice will begin cycling

the light colors. Leave the colors cycling or press the same

toggle button again to stop the color cycling. With the lights

stopped on a color pressing the Bath Light button a third

time will turn OFF the light. (A favorite color will be saved

ONLY when the cycling has been stopped on that color

and then turned OFF.)