14

07610-001-76-22-N

INSTALLATION

INSTRUCTIONS

The plumber MUST flush

the incoming water line!

DRAIN LINE

All plumbing connections must adhere to local, state, territorial, and national codes. The

installing plumber is responsible for ensuring the incoming water lines are flushed of debris

before connecting the machine. Chips and materials from cutting processes can become

lodged in the solenoid valves and prevent them from opening or closing. Any valves that

are found to be fouled or defective because of foreign matter left in the water line—and

any subsequent water damage—are not the responsibility of the manufacturer.

If water hardness tests greater than 3 GPG, install the Scaltrol Water Treatment system

(see the Plumbing Options page) into the water line before the machine’s incoming

water connection point. If water hardness tests 3 GPG or lower, install the water supply

line directly to the machine’s incoming water connection point. Iron in the water line

can cause staining. A filter designed to remove iron from the water supply is highly

recommended for supplies in excess of 0.1 ppm.

The machine

uses a flow pressure of 20 ± 5 PSI for the incoming water line. Do not

confuse static pressure with flow pressure. Static pressure occurs when there is no flow

and the valves are closed. Flow pressure occurs when water is running into the machine.

The water supply line must be 3/4" NPT minimum and must be able to provide water at t

he

minimum temperature indicated on the machine data plate.

A shut-off valve

(

not supplied

) should be installed to isolate the machine from the water

system in the event service is required. An optional shock absorber (

not supplied

) should

also be installed on the incoming water line (see the Plumbing Options page). This

prevents water hammer (hydraulic shock) from causing damage to the equipment.

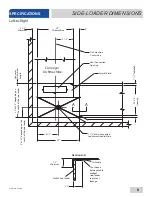

The drain for the machine is a gravity-discharge drain. All piping to the machine drain must

be a minimum 1 1/2” NPT and must not be reduced. There must be a minimum 1 1/2" air-

gap between the machine drain line and the floor drain or sink. The floor drain or sink must

be a minimum 3" NPT. If a grease trap is required by code, it should have a flow capacity

of 30 GPM. AJ-44 machines have one drain connection point and AJ-66/80 machines

have two (connected and drained into one facility floor drain or sink).

PLUMBING

i

A water hardness test

MUST be performed.

Machine

Drain Line

1 1/2” [38 mm]

MIN, Must NOT

Be Reduced.

Pitch 1/4” per ft.

Must Install Machine

Drain Line above

3” [76 mm] MIN

Floor Drain or Sink

1 1/2”

[38 mm]

MIN

Air-gap

Drain

Connection

1 1/2

[38 mm]

!

CAUTION

CAUTION! An air-gap

is required between the

drain line and floor drain

or sink.

Summary of Contents for AJ-44

Page 72: ...64 07610 001 76 22 N PARTS AJ 66 RACK RAILS Left to Right Right to Left 1 4 2 3 4 5 6 7 1 ...

Page 84: ...76 07610 001 76 22 N SCHEMATICS AJ 44CGP 208 230 V 60 HZ 1 PHASE AJ 44CGP SCHEMATIC ...

Page 85: ...07610 001 76 22 N 77 SCHEMATICS AJ 44CGP 208 230 V 60 HZ 3 PHASE AJ 44CGP SCHEMATIC ...

Page 86: ...78 07610 001 76 22 N SCHEMATICS AJ 44CGP 460 V 60 HZ 3 PHASE AJ 44CGP SCHEMATIC ...

Page 87: ...07610 001 76 22 N 79 SCHEMATICS AJ 66CGP 208 230 V 60 HZ 1 PHASE AJ 66CGP SCHEMATIC ...

Page 88: ...80 07610 001 76 22 N SCHEMATICS AJ 66CGP 208 230 V 60 HZ 3 PHASE AJ 66CGP SCHEMATIC ...

Page 89: ...07610 001 76 22 N 81 SCHEMATICS AJ 66CGP 380 460 600 V 60 HZ 3 PHASE AJ 66CGP SCHEMATIC ...